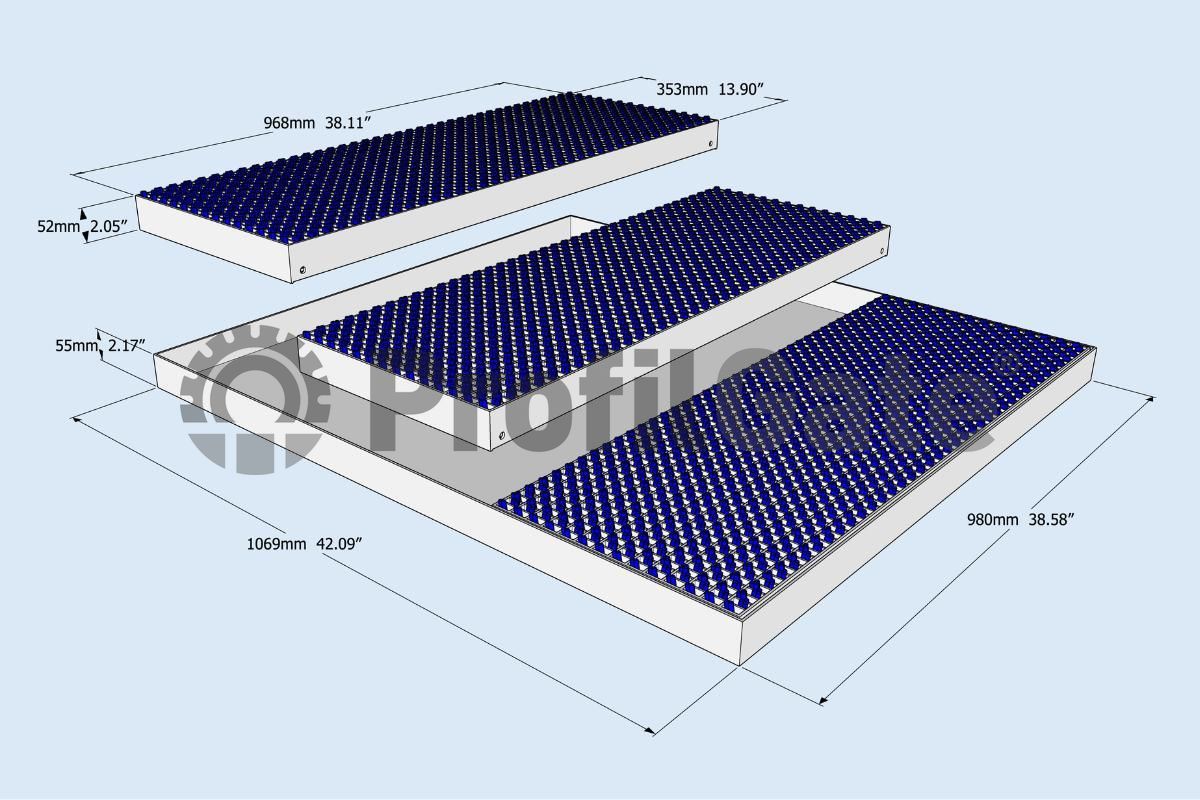

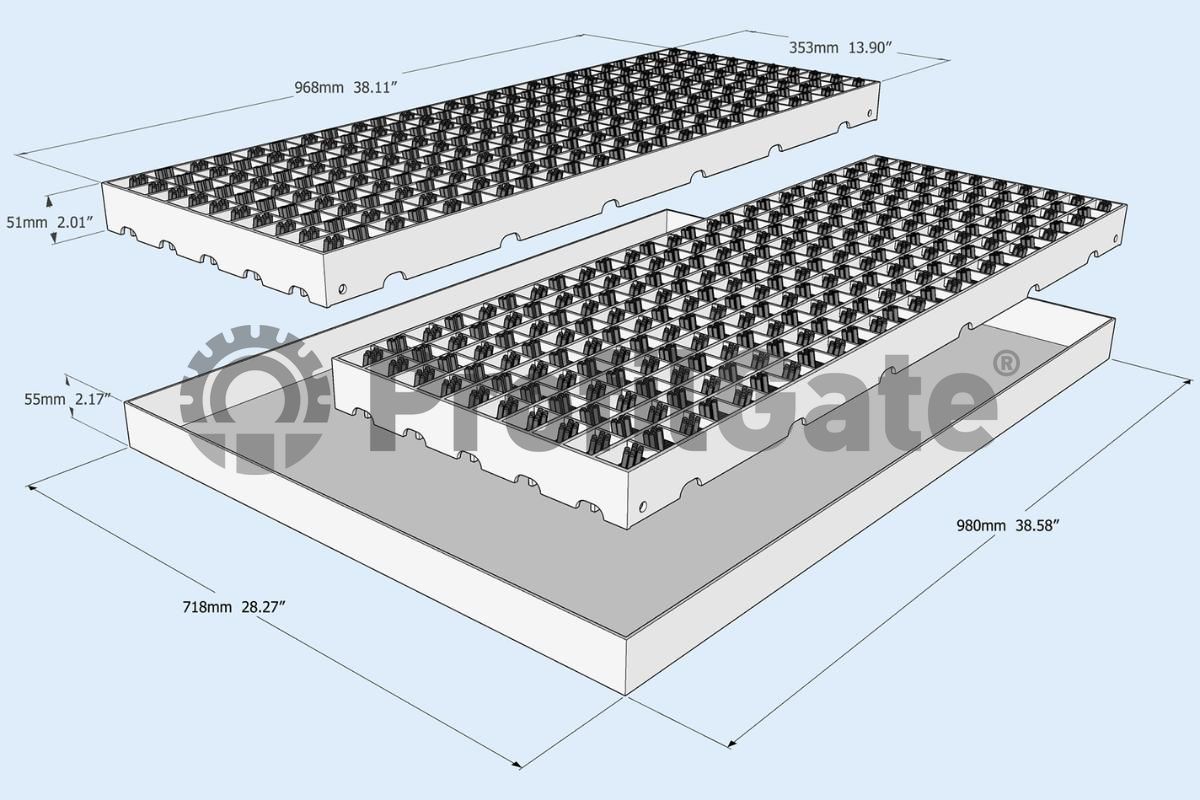

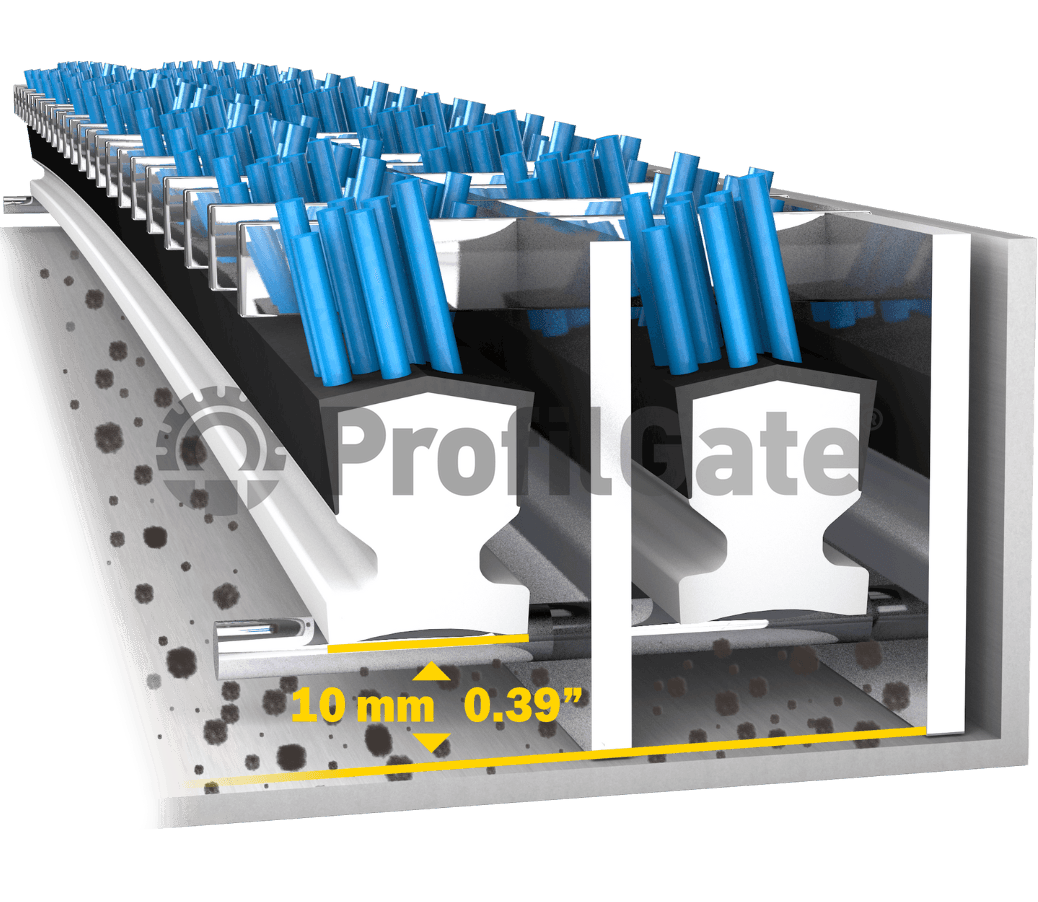

Maintaining a clean and organized environment is a fundamental aspect of any industrial setting. From warehouses to production plants, cleanliness not only ensures a safe and efficient workflow but also reflects a commitment to quality. However, relying solely on regular cleaning measures may fall short when it comes to preventing the spread of dirt and contaminants within your facility. Enter ProfilGate

®—a groundbreaking solution that goes beyond traditional cleaning by actively preventing dirt ingress, safeguarding your operations in a proactive manner.

ProfilGate

® introduces a paradigm shift in the world of industrial cleanliness. Unlike conventional cleaning methods that merely clean up after the fact, the ProfilGate

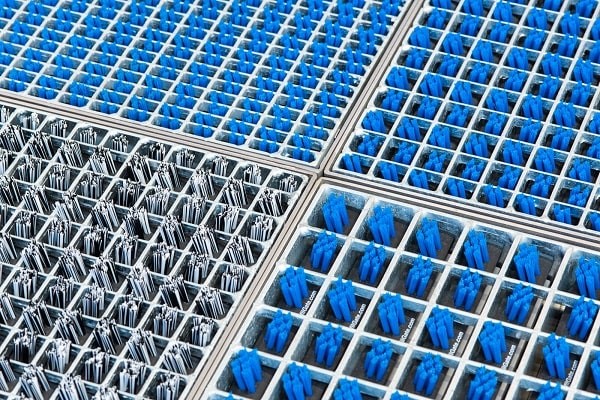

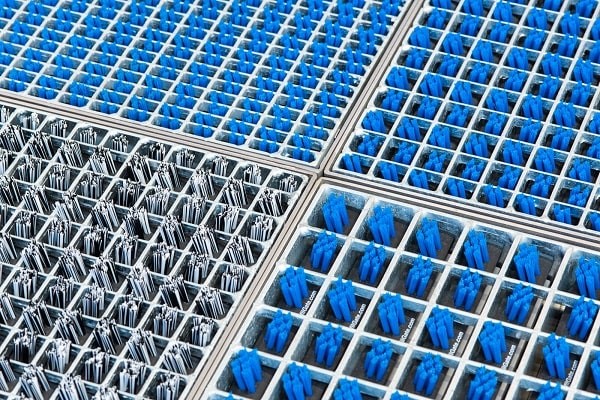

® system takes a proactive stance by preventing dirt from spreading in the first place through an innovative design that targets wheels—vehicles’ primary points of contact with external contaminants. ProfilGate

® not only addresses coarse dirt and tire marks on your logistics premises but also extends its preventive capabilities to tackle even the smallest particles. Inside warehouses, rubber abrasion from tires often accumulates as dust on shelves and crates, a space that traditional cleaners struggle to reach. This proactive approach intercepts and eliminates particle distribution, particularly crucial in environments where technical cleanliness is of paramount importance.

How could ProfilGate® be applied?

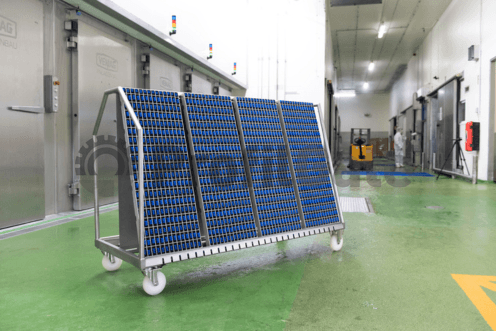

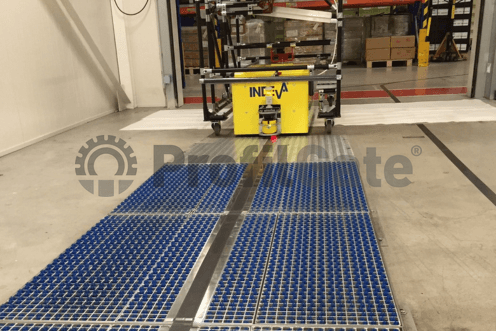

- Logistics Area Entry: ProfilGate® takes the dirt off trucks as they enter the logistics area, curtailing the influx of contaminants at the very entrance.

- Forklifts and Pallet Trucks: Vehicles commonly used for material handling often carry dirt and dust from one area to another. ProfilGate® cleans these vehicles’ wheels, preventing them from transporting contaminants further inside the facility.

Click Here to learn more about ProfilGate®!

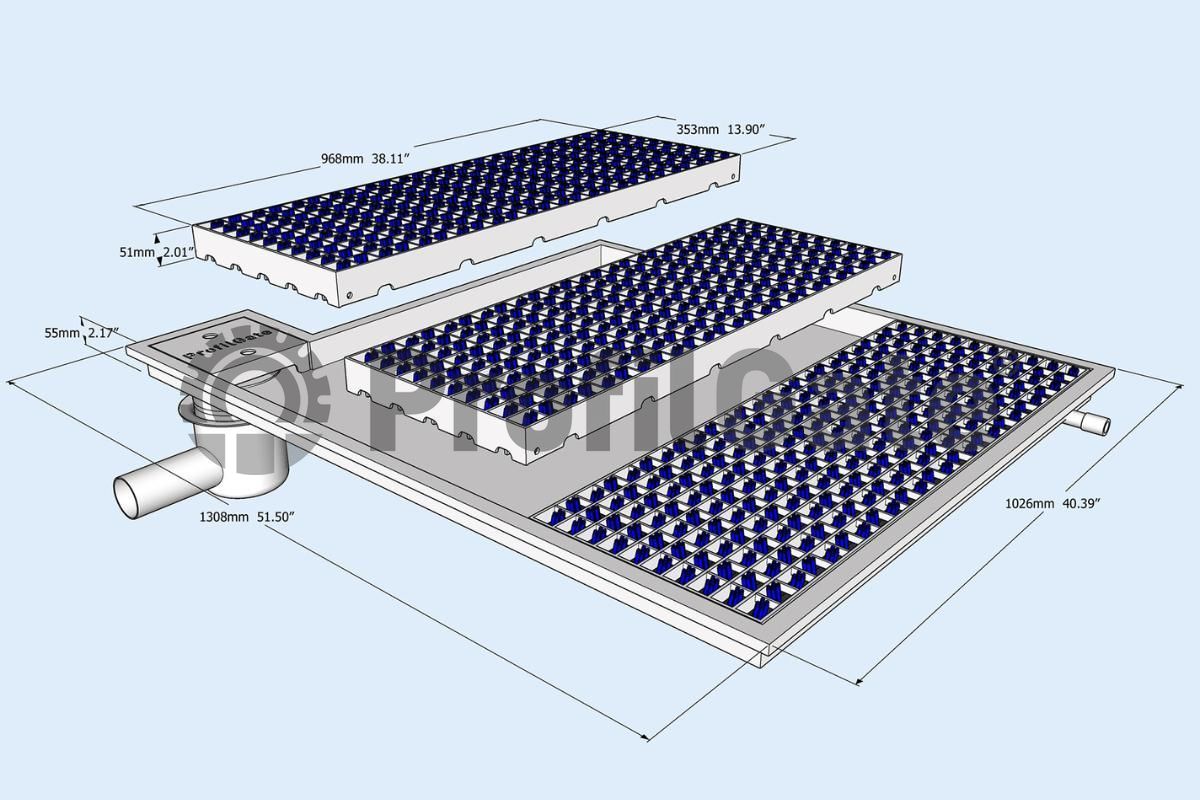

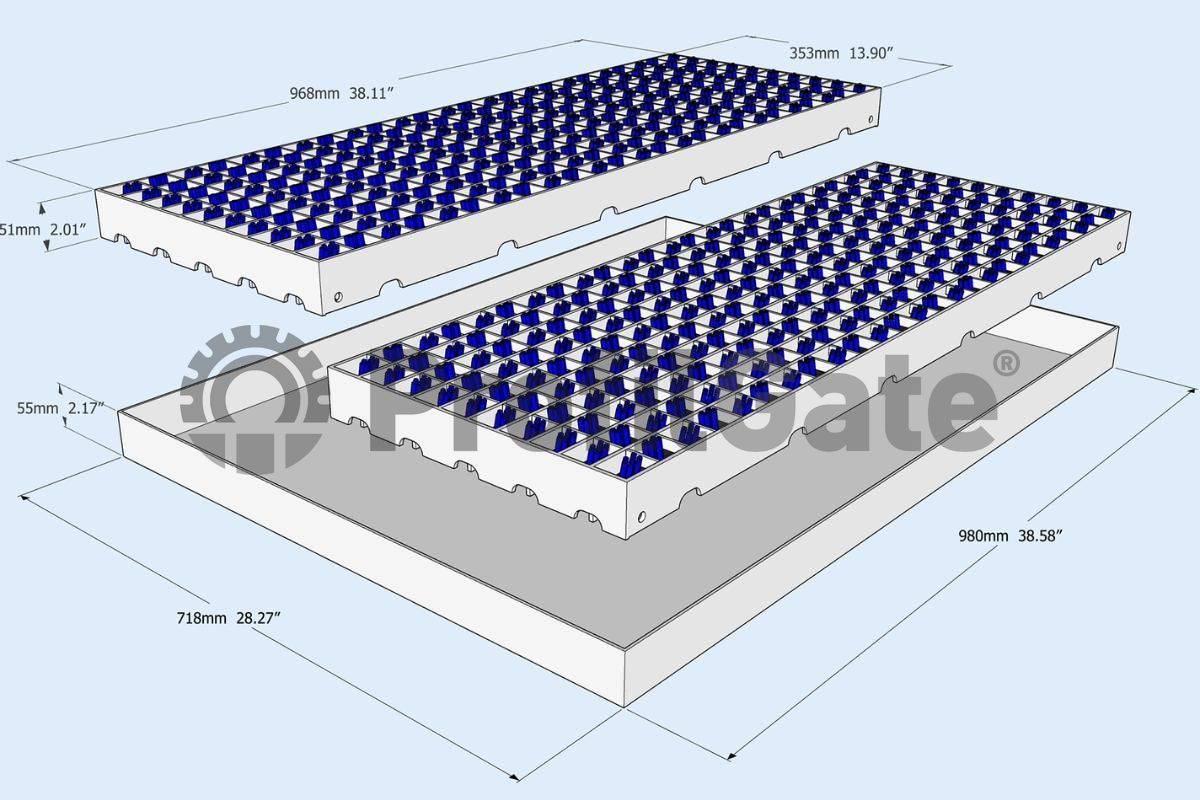

Maintaining a clean and organized environment is a fundamental aspect of any industrial setting. From warehouses to production plants, cleanliness not only ensures a safe and efficient workflow but also reflects a commitment to quality. However, relying solely on regular cleaning measures may fall short when it comes to preventing the spread of dirt and contaminants within your facility. Enter ProfilGate®—a groundbreaking solution that goes beyond traditional cleaning by actively preventing dirt ingress, safeguarding your operations in a proactive manner.

ProfilGate® introduces a paradigm shift in the world of industrial cleanliness. Unlike conventional cleaning methods that merely clean up after the fact, the ProfilGate® system takes a proactive stance by preventing dirt from spreading in the first place through an innovative design that targets wheels—vehicles’ primary points of contact with external contaminants. ProfilGate® not only addresses coarse dirt and tire marks on your logistics premises but also extends its preventive capabilities to tackle even the smallest particles. Inside warehouses, rubber abrasion from tires often accumulates as dust on shelves and crates, a space that traditional cleaners struggle to reach. This proactive approach intercepts and eliminates particle distribution, particularly crucial in environments where technical cleanliness is of paramount importance.

How could ProfilGate® be applied?

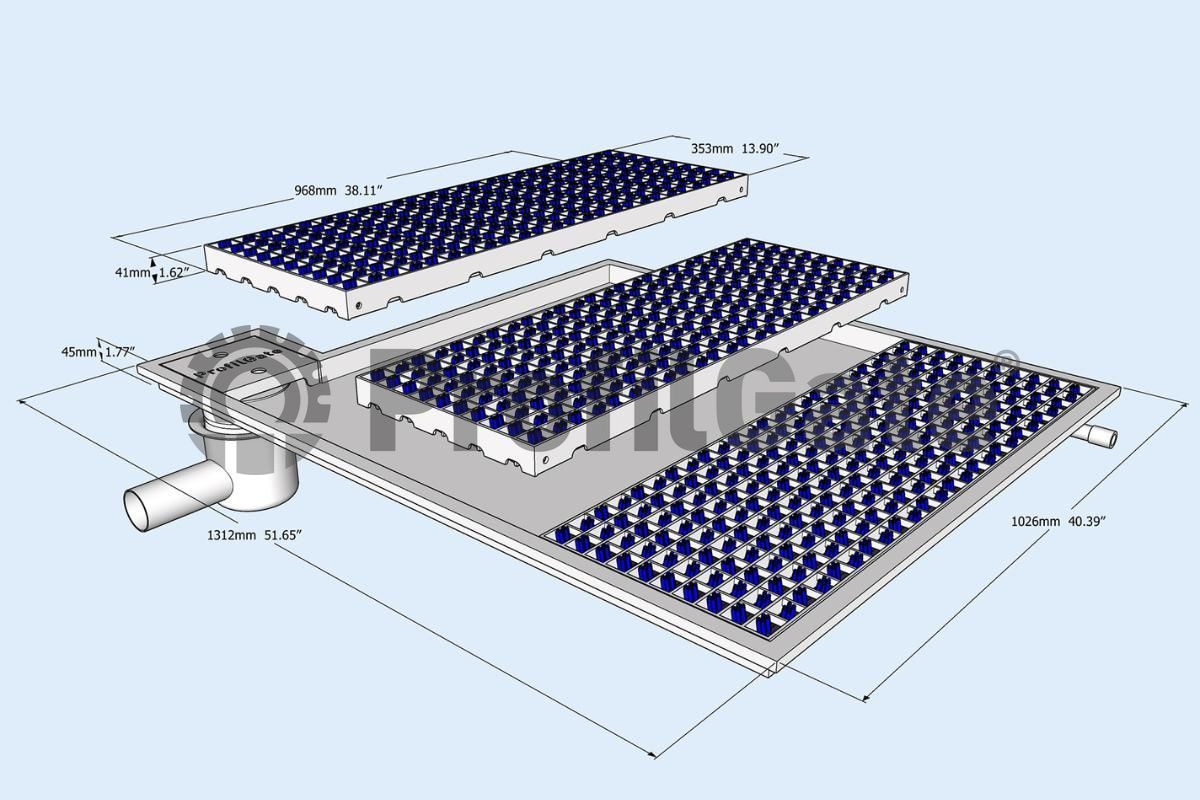

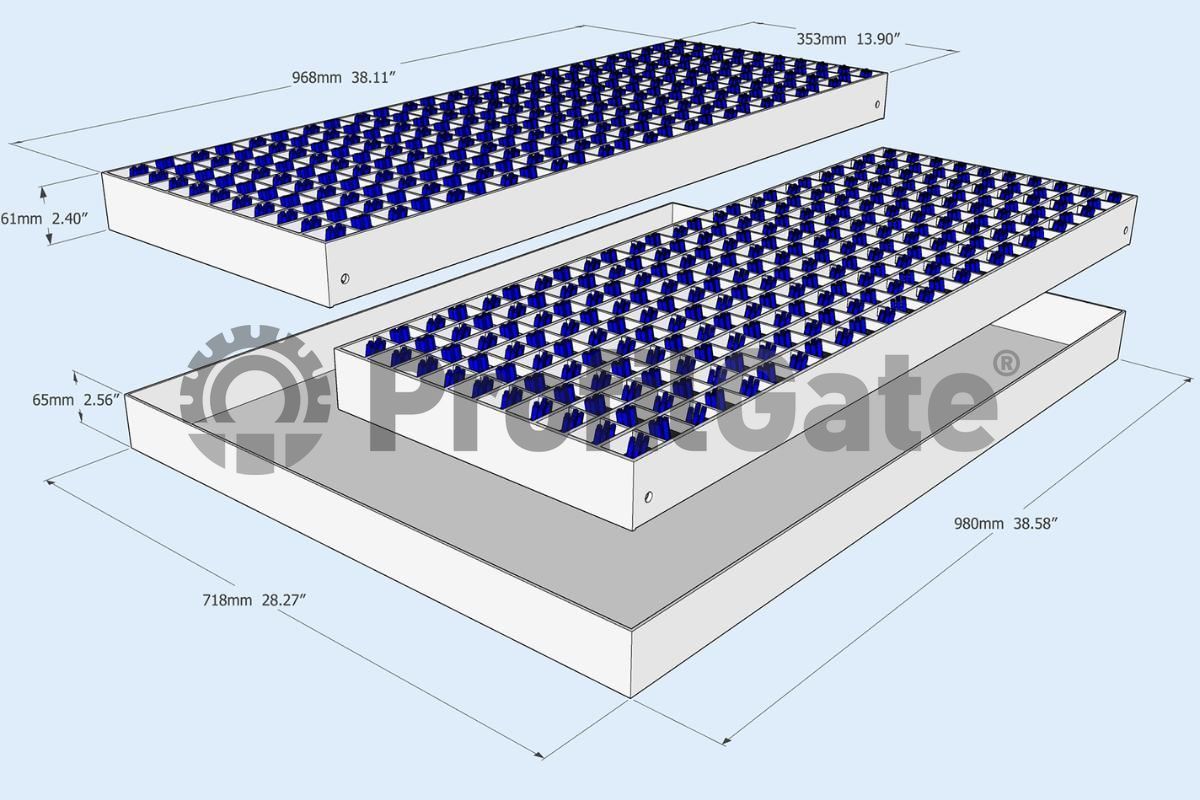

Maintaining a clean and organized environment is a fundamental aspect of any industrial setting. From warehouses to production plants, cleanliness not only ensures a safe and efficient workflow but also reflects a commitment to quality. However, relying solely on regular cleaning measures may fall short when it comes to preventing the spread of dirt and contaminants within your facility. Enter ProfilGate®—a groundbreaking solution that goes beyond traditional cleaning by actively preventing dirt ingress, safeguarding your operations in a proactive manner.

ProfilGate® introduces a paradigm shift in the world of industrial cleanliness. Unlike conventional cleaning methods that merely clean up after the fact, the ProfilGate® system takes a proactive stance by preventing dirt from spreading in the first place through an innovative design that targets wheels—vehicles’ primary points of contact with external contaminants. ProfilGate® not only addresses coarse dirt and tire marks on your logistics premises but also extends its preventive capabilities to tackle even the smallest particles. Inside warehouses, rubber abrasion from tires often accumulates as dust on shelves and crates, a space that traditional cleaners struggle to reach. This proactive approach intercepts and eliminates particle distribution, particularly crucial in environments where technical cleanliness is of paramount importance.

How could ProfilGate® be applied?

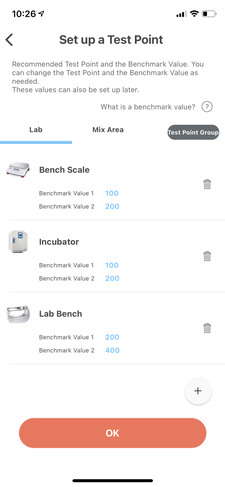

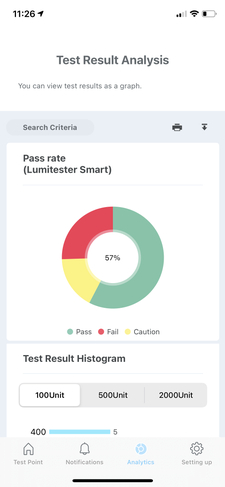

Exportable Data and Reports for Regulatory Compliance

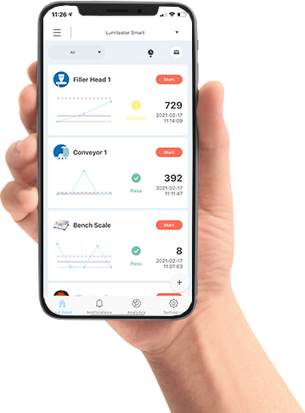

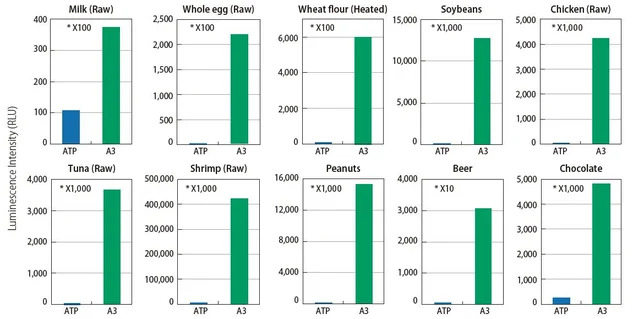

Exportable Data and Reports for Regulatory Compliance See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t