Description

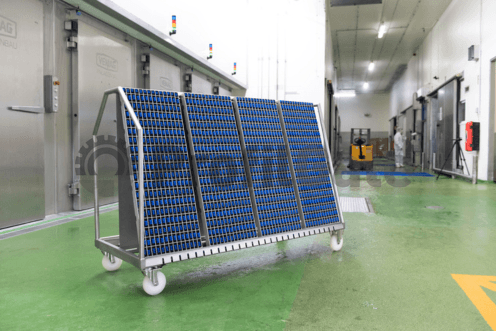

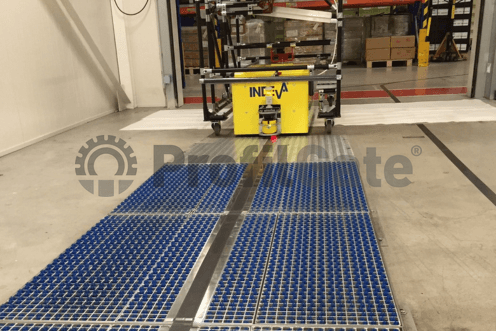

ProfilGate® XS Creates A Clean Driving Zone Especially For Very Narrow Rollers Of Intelligent Automated Guided Vehicles (AGVs)

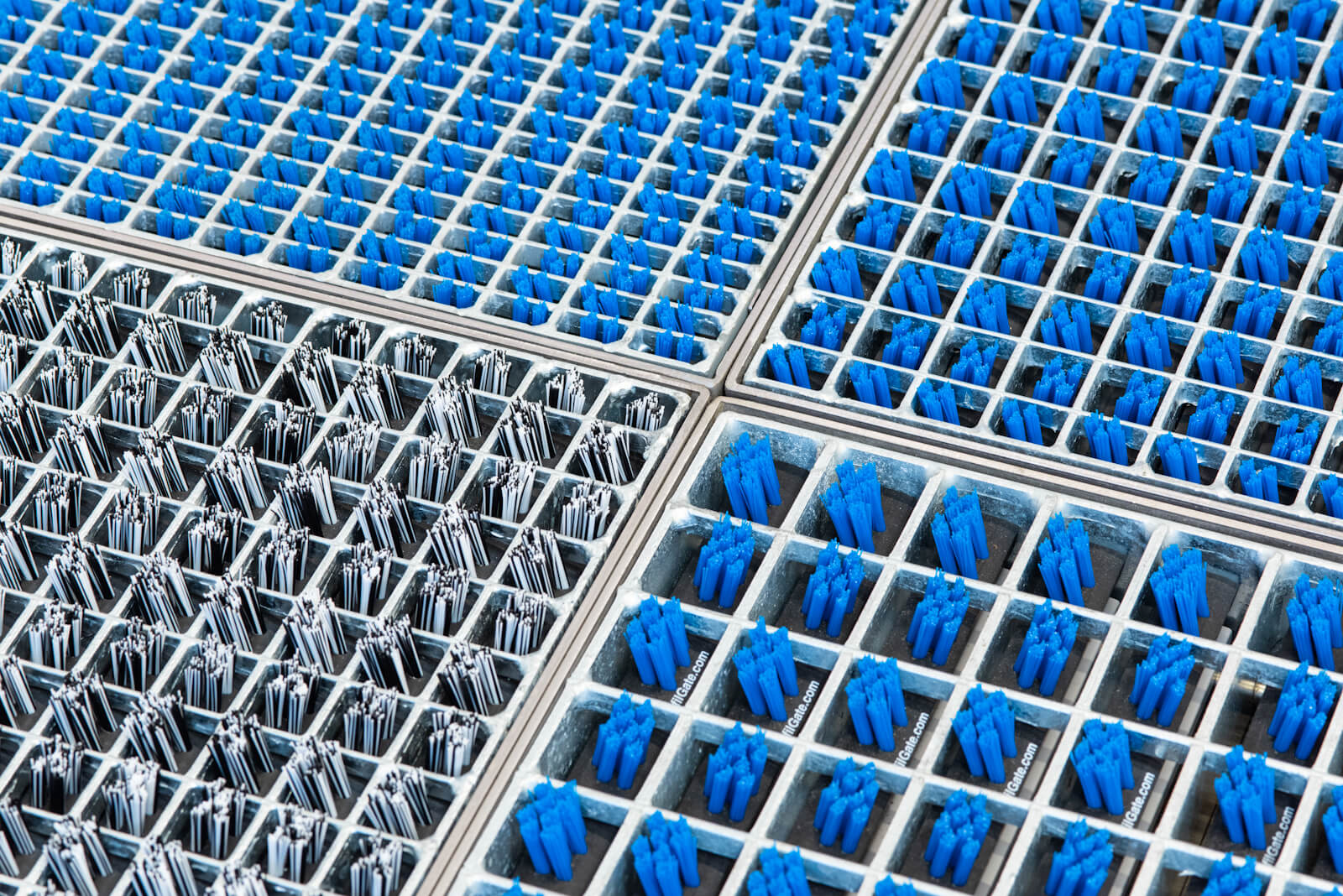

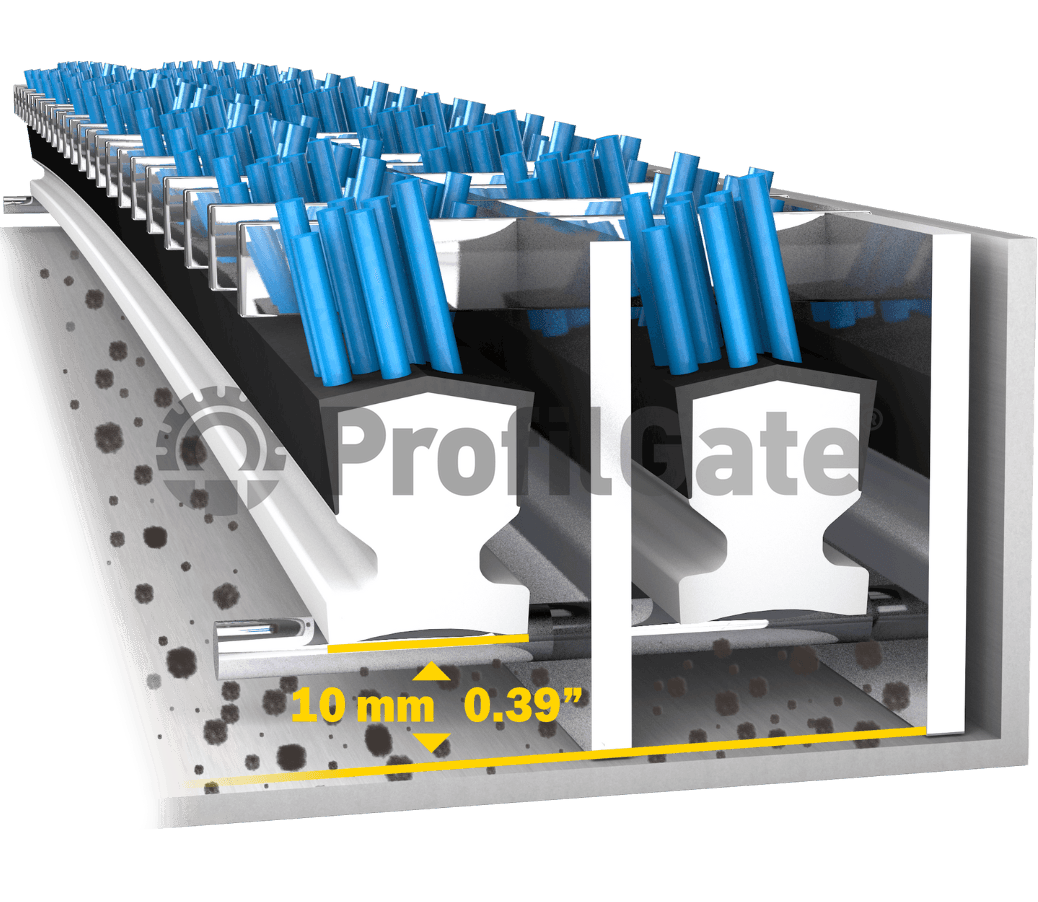

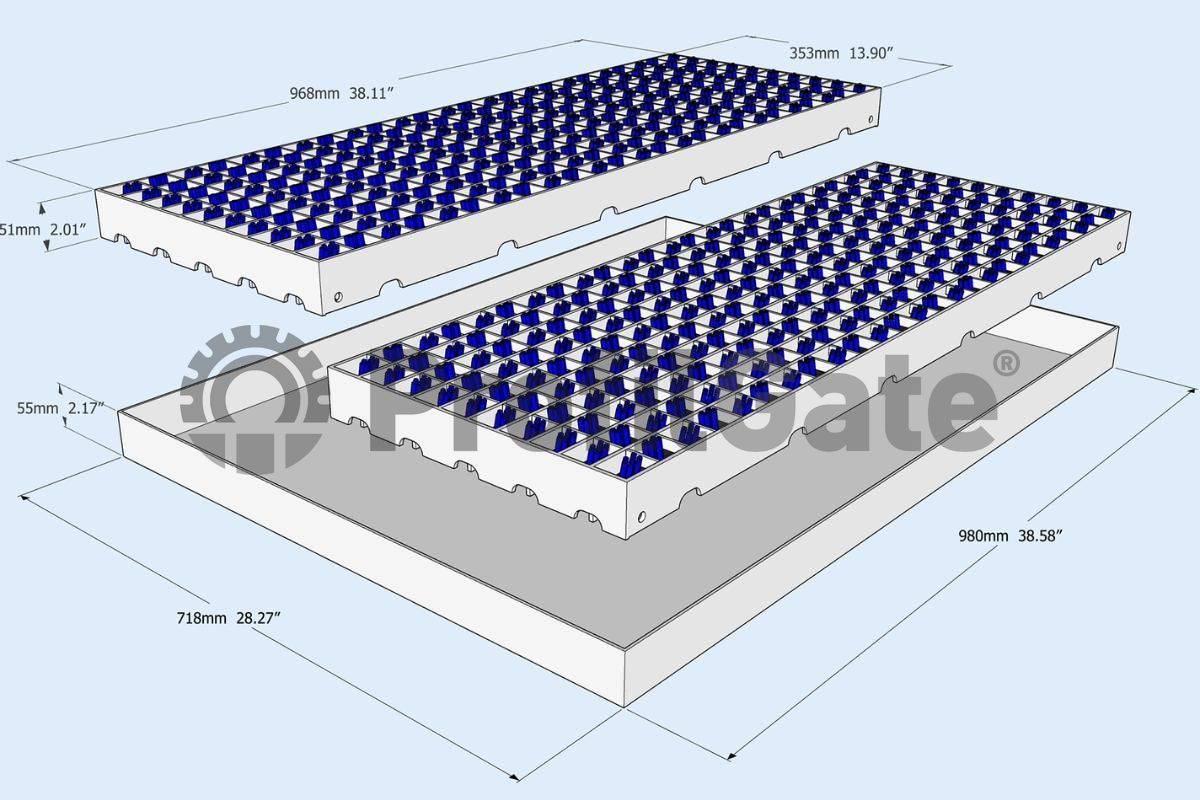

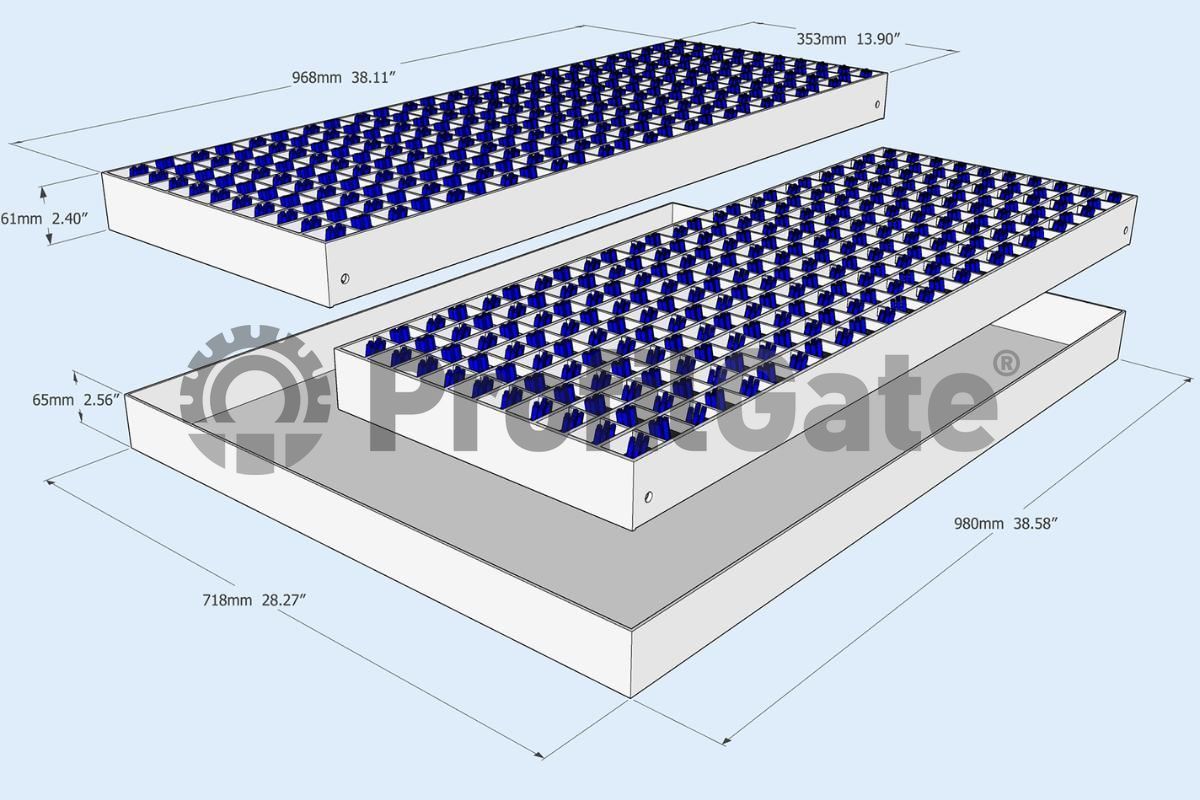

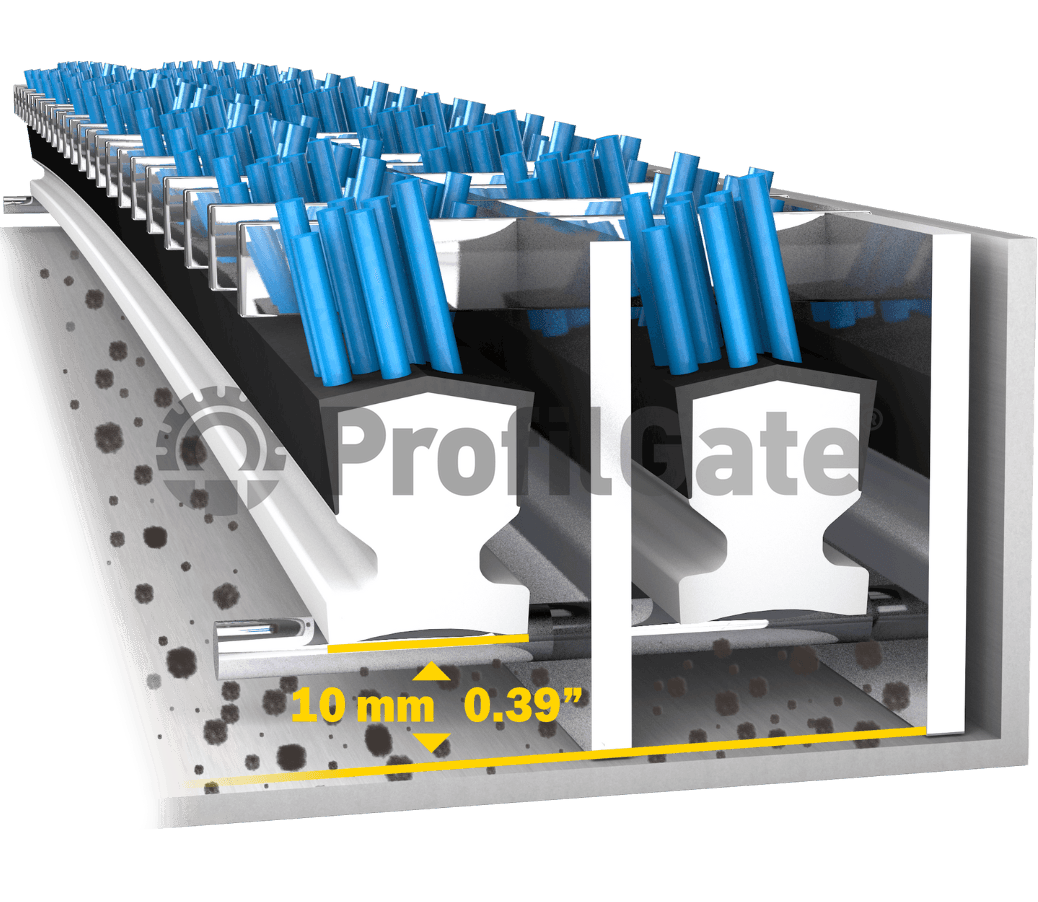

The brush grate is particularly close-meshed, creating a smooth surface and allowing the AGVs rollers to travel evenly over the cleaning field with little vibration.

Requirement for clean tires is very high since AGVs always drive the same route, and if dirt is carried on the tires, it quickly damages the floors in the same area every time. We meet the requirements of less vibrations and a good cleaning effect with the new ProfilGate® XS System.

The new XS model is based on the ST- model but has halved cells and modified bristles on the brush body. It is intended for cleaning AGV tires.

Since the tires of AGVs are often smaller and thinner, the B- and ST-versions are sometimes not suitable because the crossing of ProfilGate® is too shaky.

In addition, the requirements for low vibration are very high due to the high sensitivity of the electrical components of AGVs.

ProfilGate® xs series Models:

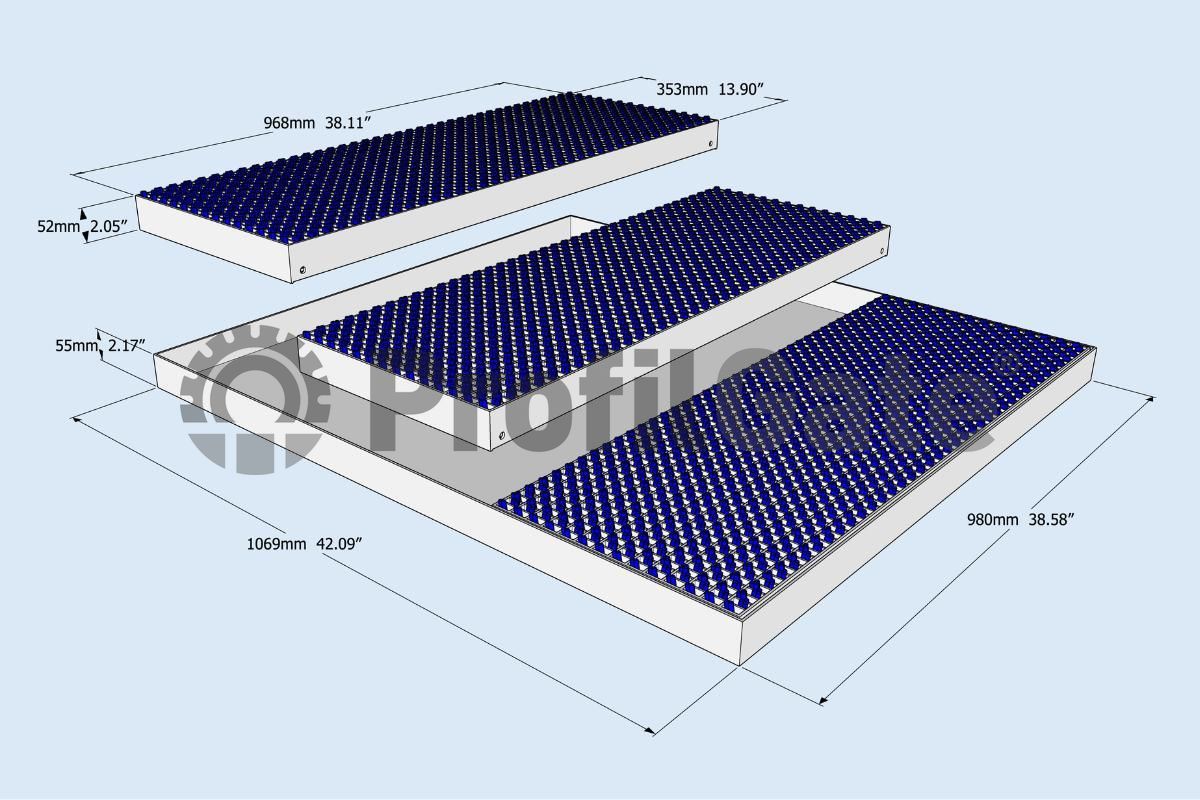

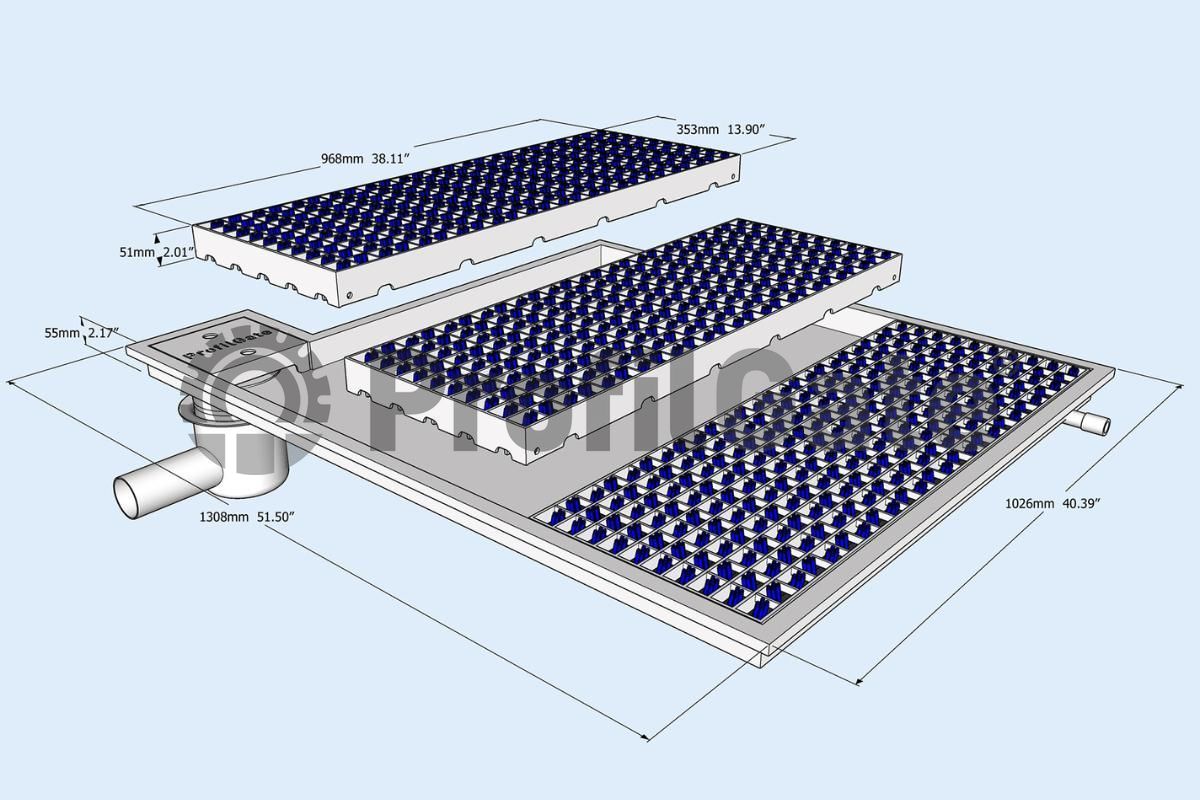

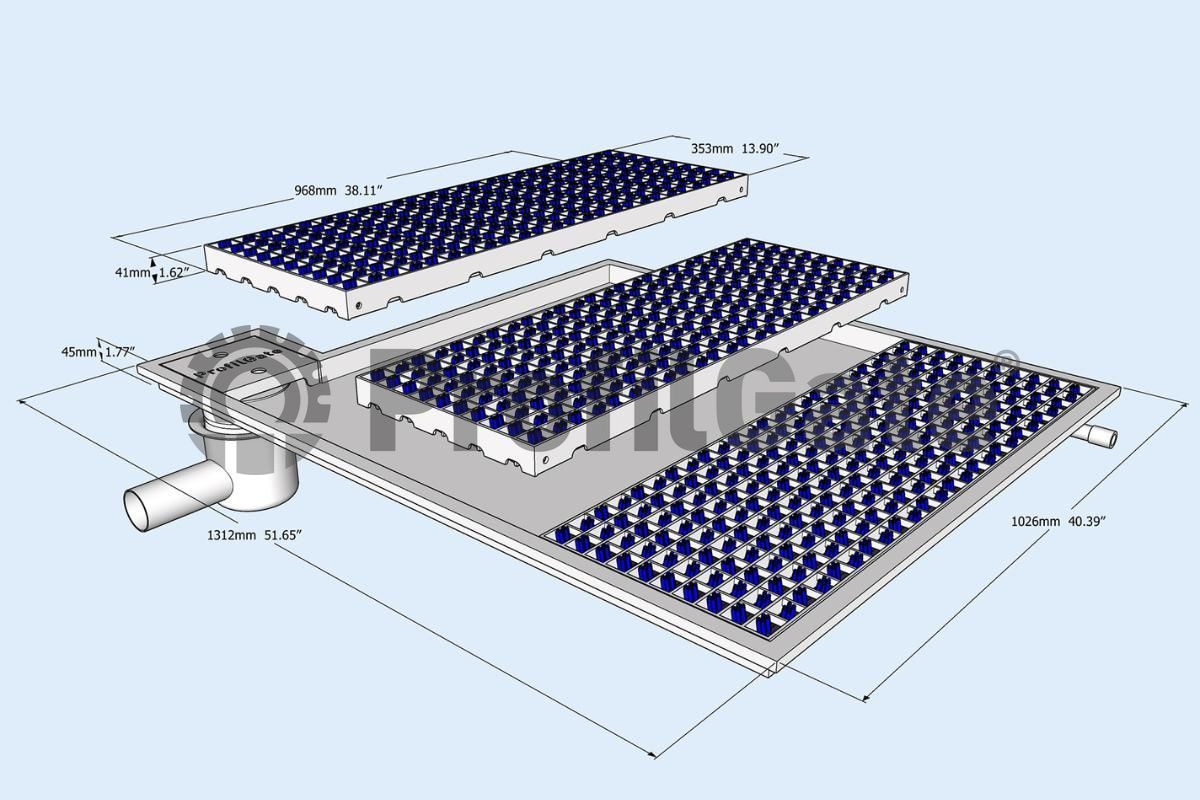

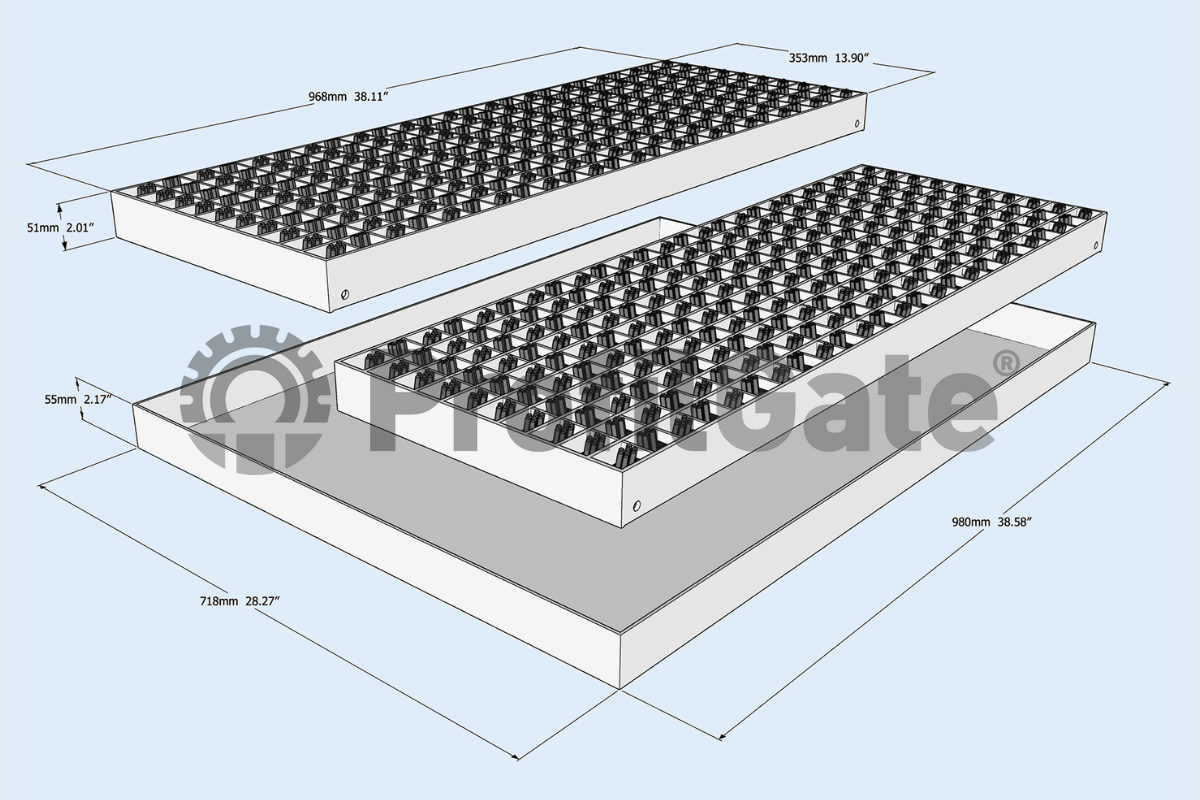

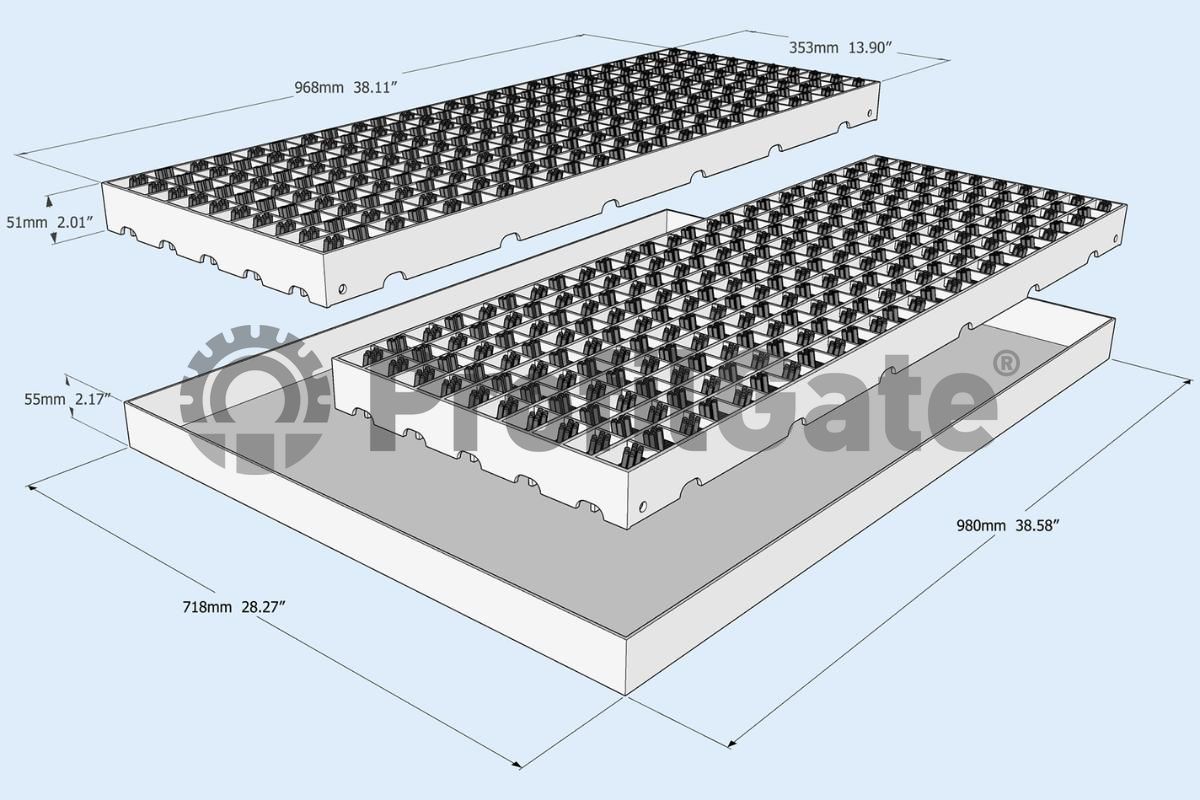

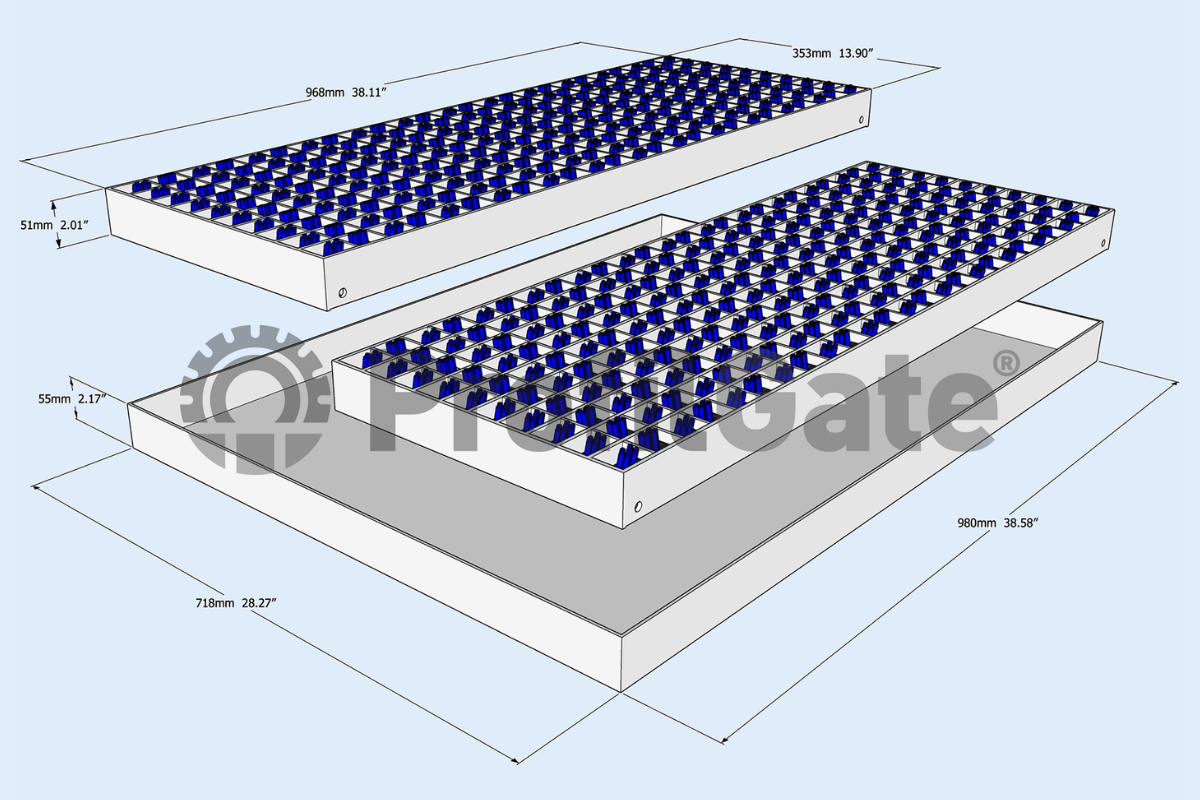

ProfilGate® xs 55

Reliable cleaning of the rollers

Reduced dirt carryover

Integration into existing transport routes

Suitable for any navigation methods

Designed for small AGV rollers

Plain and smooth grate surface

10 mm dirt-collecting container

For > 100 passages per day

Hygienic and process-safe

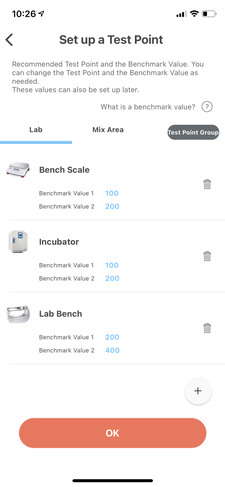

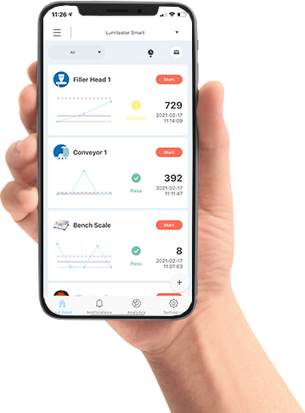

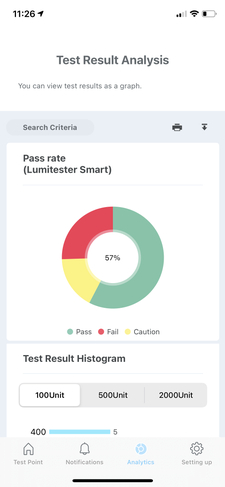

Exportable Data and Reports for Regulatory Compliance

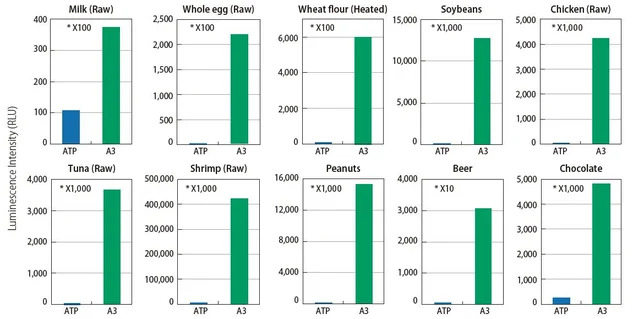

Exportable Data and Reports for Regulatory Compliance See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t