Description

PhageGuard contributes to safer food production by using phages. As the natural enemy of bacteria, phages specifically kill pathogens like Salmonella, and leave the good ones intact. They are green, smart and easy to apply on food via spraying, misting or dipping. Phages can also be used directly on food contact surfaces or in the processing environment. Using PhageGuard as a surface intervention to enhance consumer safety.

A 100 percent natural and organic solution, PhageGuard S is FDA-approved to specifically combat Salmonella.

The PhageGuard advantage is precision. It is targeted to eliminate Salmonella in your food products, without affecting taste, odor or texture.

How To Use

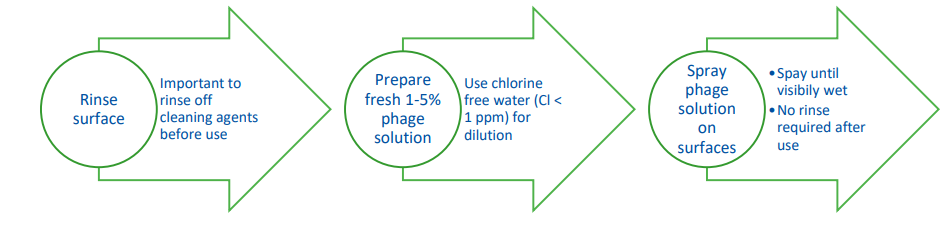

• Rinse off other chemical cleaning agents from the surface if used before.

• Do NOT let chemical residues come in contact with prepared phage solution.

• Use phage solution as a last step in your sanitizing procedure.

• Use clean, rinsed spray canister/installation. Do NOT let chemical residues come in contact with prepared phage solution.

• Use dechlorinated water (Cl <1 ppm). A chlorine filter will remove chlorine from water.

• Dilution 1 % : add one 100mL bottle of PhageGuard for 2.5 gallons of water.

• Dilution 5 % : 5 X 100 mL bottles for 2.5 gallons of water.

• 2.5 gallon of phage solution can treat approx. 1000 ft2.

• Prepared solution can be stored refridgerated (39 ºF) for 48 hours only.

• Spray on surface until visibly wet. No need to rinse after spray.

• Phages work up to 24 hours upon treatment. Recommend to spray end of shift so has phages to work overnight/weekend.

• Food contact surfaces: recommeded to spray daily.

• Biofilms: Spray 1 – 3 times after area has dried. Swab, if tested positive repeat until Listeria will test negative for 3 consecutive days. Biofilms should be eradicated in 2-7 treatments.

• Food processing environments: spray phage solution weekly/biweekly.

• Leftover phage solution should be stored refridgerated (39 ºF).

Advantages

- Leads to 1-3 log10 initial reductions in pathogens

- Effective against all Salmonella species

- Hinders proliferation of Salmonella

- No organoleptic influence

- No need to reformulate products

- No trade off between quality and safety

- Non corrosive to equipment

- Suitable for natural & organic product

- Does not dissolve fat

- Does not react away in the presence of organic matter

- Can be used post-slaughter or in later processing stages

- Highly effective at killing Salmonella which was demonstrated in a 2014 study by Certified Laboratories (CFS) in California

Download

Articles

- Effects on Salmonella population in final ground products

- Bacteriophage Applications for Food Production and Processing

- Effect of ultraviolet light, organic acids, and bacteriophage on Salmonella populations in ground beef

- Effects of bacteriophages and peroxyacetic acid applications on beef contaminated with Salmonella during different grinding stages

- Salmonella Typhimurium DT 104 response to Lytic bacteriophage and Lactobionic acid on raw chicken breast

- Salmonella spp. Response to Lytic Bacteriophage and Lactic Acid on Marinated and Tenderized Raw Pork Loins

Applications

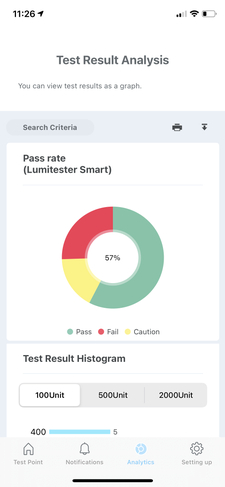

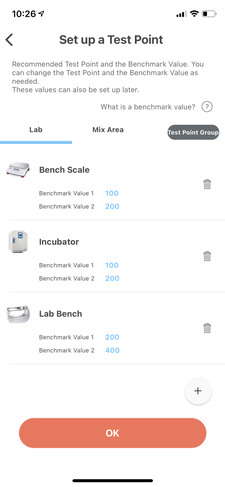

Exportable Data and Reports for Regulatory Compliance

Exportable Data and Reports for Regulatory Compliance

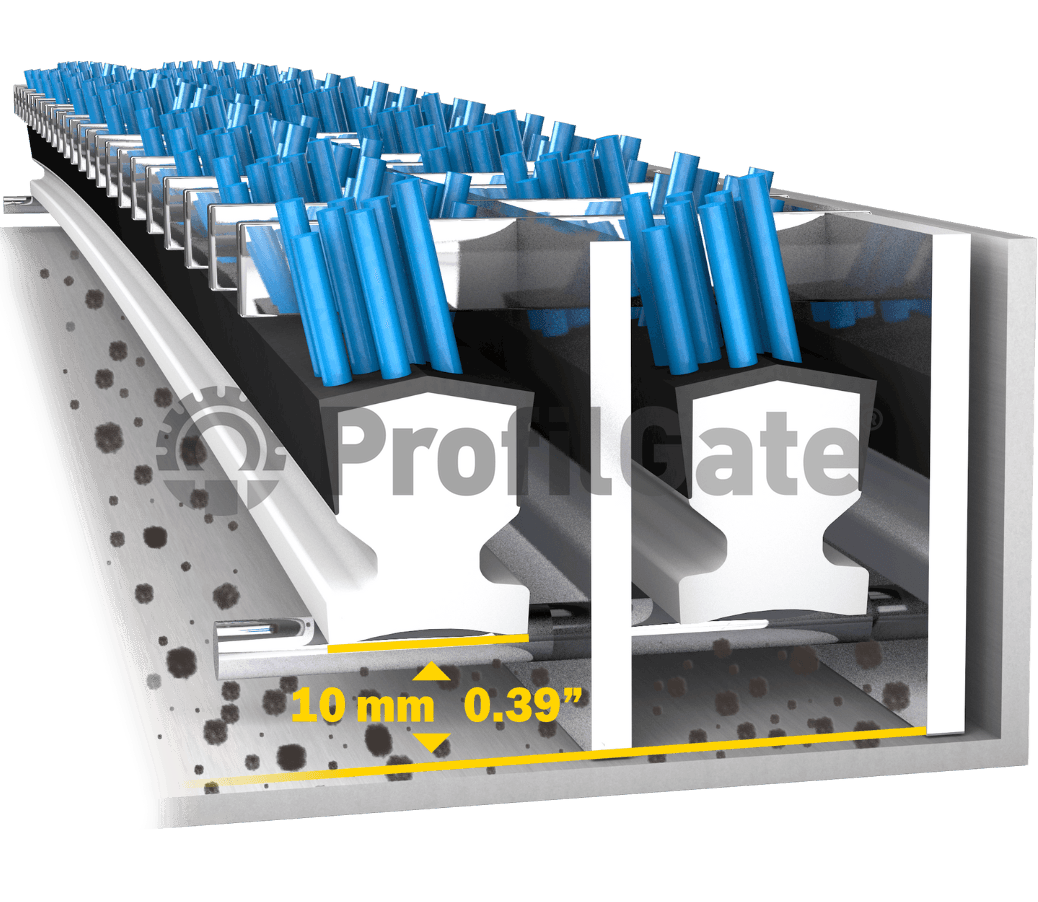

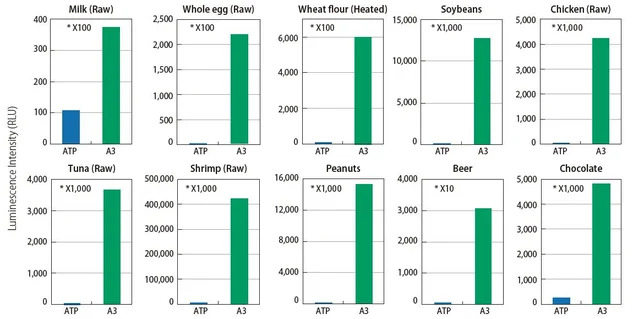

See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t