Description

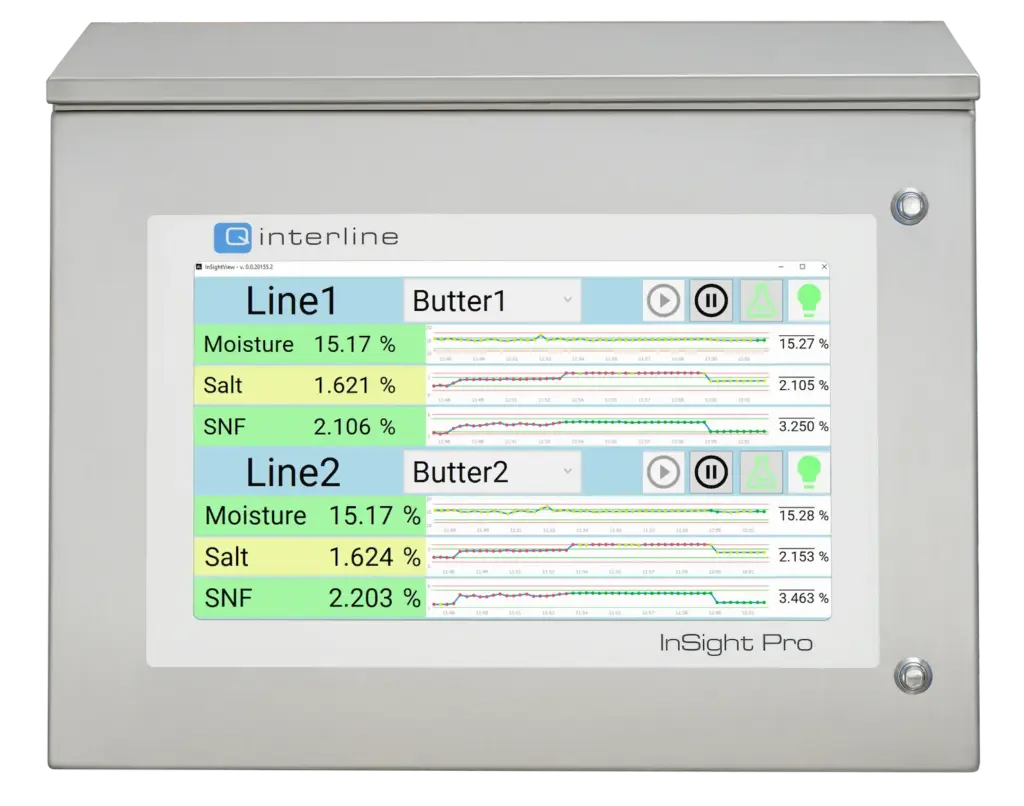

InSight Pro in-line NIR Analyser for production optimization with real-time process insights

With Q-Interline’s in-line process analysis solution, InSight Pro, you can transfer calibrations from at-line to in-line and get a synergy between at-line and in-line analysis. InSight Pro offers measuring devices adapted for various sample types. One or two measuring points can connect to the analyser via flexible optical fibres.

The solution is easy to install and use. We make sure you get a fast return on investment with our unique implementation project plan with full support. InSight Pro is always up and running with fast start-up after production pause and with a link to our cloud-based surveillance software, AnalyticTrust, for your reassurance 24/7.

How it works

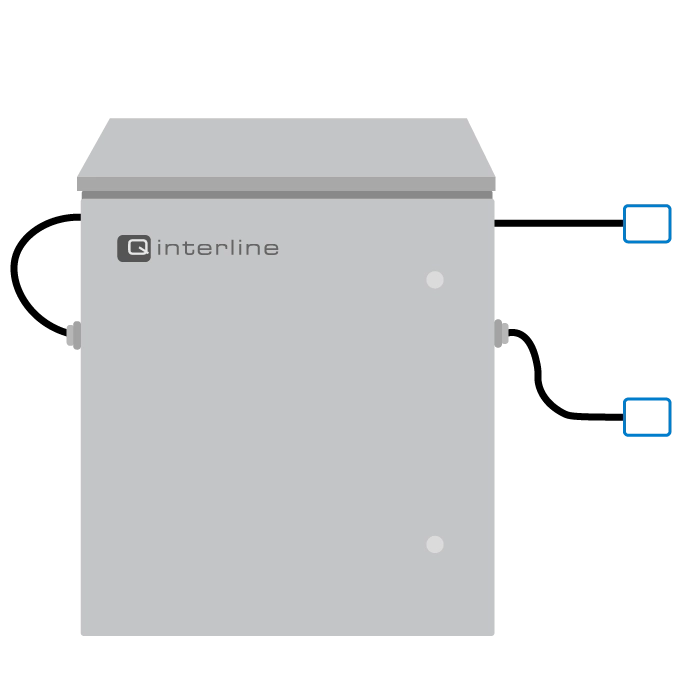

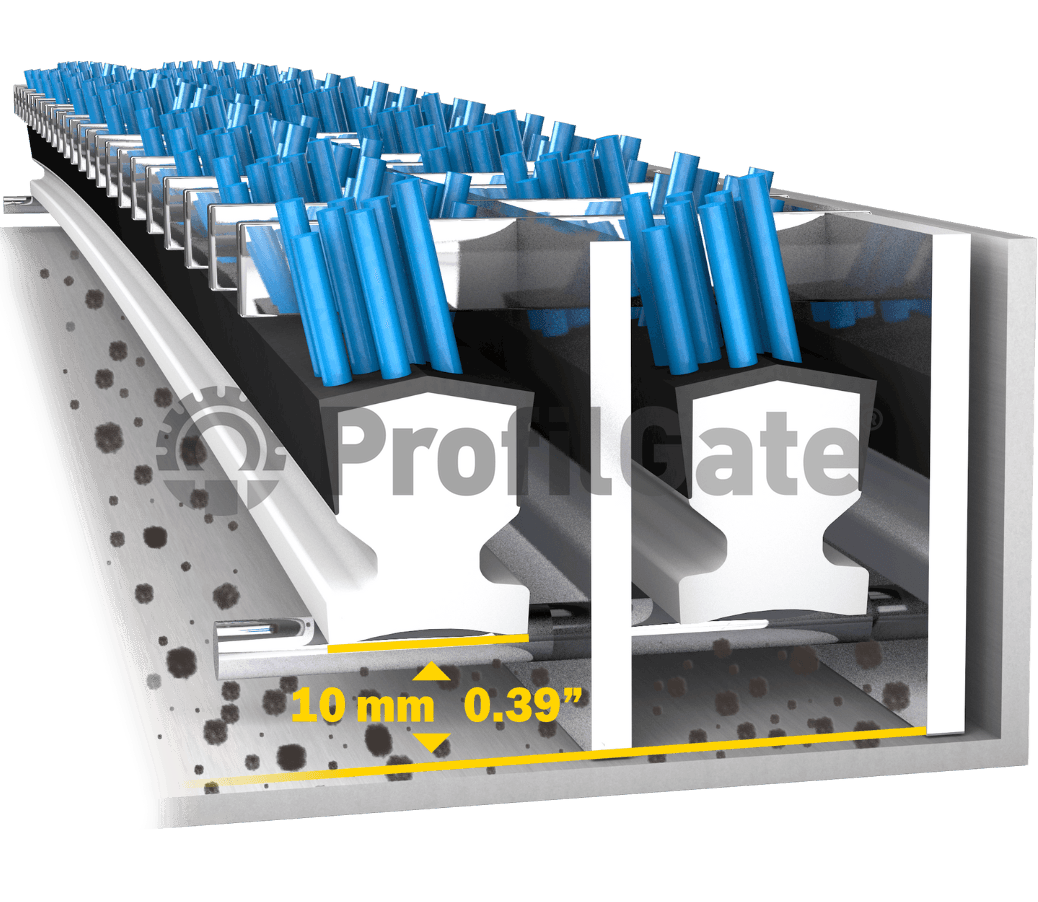

The base analyser is the Quant analyser. Sampling devices connect to the analyser through fibre optical cables from 5 to 30 metres. Fibre cables are self-contained in white food-grade hoses, which are easy to install in cable trays. The system is fully CIP/SIP compliant and is specified to work up to 10 bar pressure with operating temperatures from 5 to 90 C.

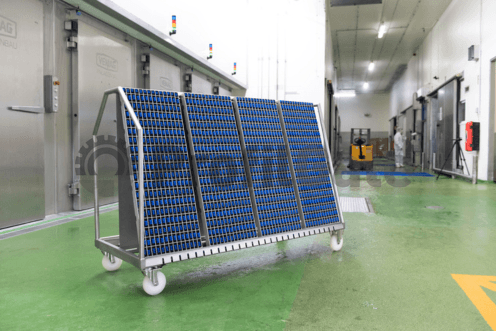

We develop, patent, and produce a variety of different probes and cells which connect to the InSight Pro utilizing optical cables to maximise flexibility.

You can analyse various products in-line

With Q-Interline’s in-line solution, InSight Pro, you can measure many different types of products. You can even measure two different product types with the same in-line solution. Analyse:

- Liquids

- Powders

- Semi-solids

- Pasty products

Samples can be made both in-tank, in-pipe, and cross-pipe.

14 reasons to choose InSight Pro for in-line analysis:

- A maintenance-free system

- Up to two measuring points with just one analyser

- 3-years hardware warranty

- A choice between five configurations

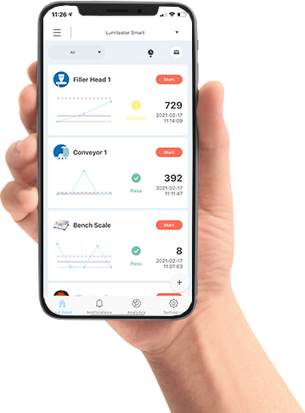

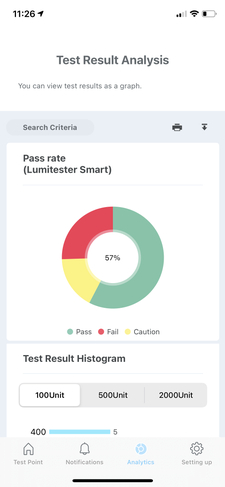

- Optional built-in 24/7 surveillance with AnalyticTrust

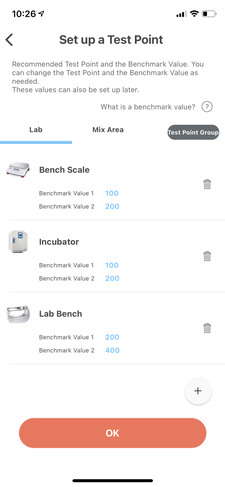

- Operator-friendly software — InSightView

- Faster start-up after production pause

- Stable and predictable production process

- Production closer to the target

- Less waste and rework

- Full traceability and documentation

- Energy optimisation

- CIP/SIP compliant solution specified to work up to 10 bar pressure and operating temperatures from 5 to 90 C.

- IP65 protection for easy installation

Optimised sampling solutions

Applying the correct sampling is not guaranteed by simply going in-line. The probes and cells must see the true process variations without bias and sampling error. Equally important is the design of a manual sample extraction point, ensuring the important validation step.

All probes and cells are designed to meet strict hygienic requirements. The sampling systems all comply with CE norms, such as EN1935/2004, and the only contact materials are SS316L, Sapphire, and Teflon.

Exportable Data and Reports for Regulatory Compliance

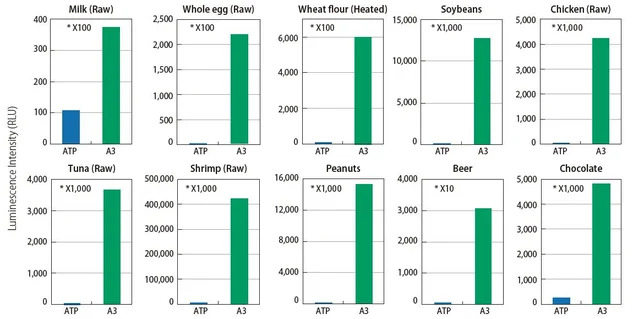

Exportable Data and Reports for Regulatory Compliance See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t