Description

Effective Wet Cleaning And Optional Disinfection For Bigger Wheels

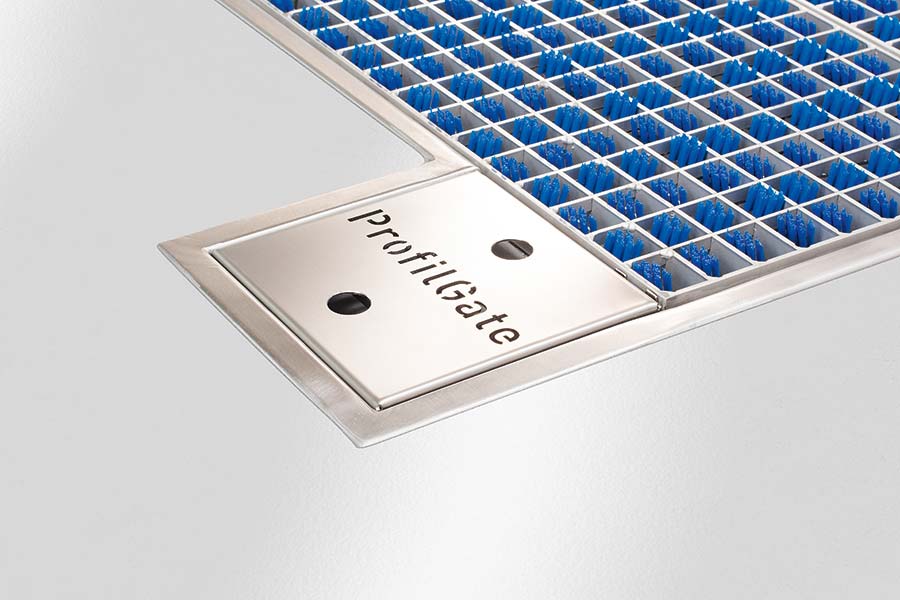

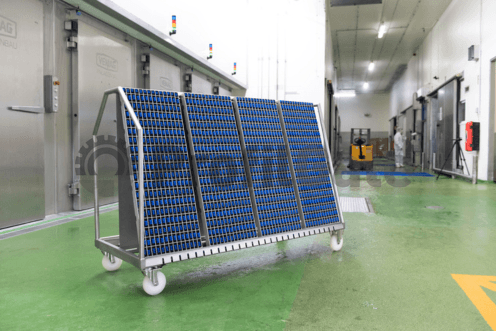

The clean zones of the i-aqua series are designed for wet cleaning and disinfection of tires, rollers, wheels and shoe soles. As in the names of the other ProfilGate® series, the “i” is an abbreviation for “Inox steel”. The material is rustproof and therefore ideal for areas with high hygiene requirements, such as those in the food industry.

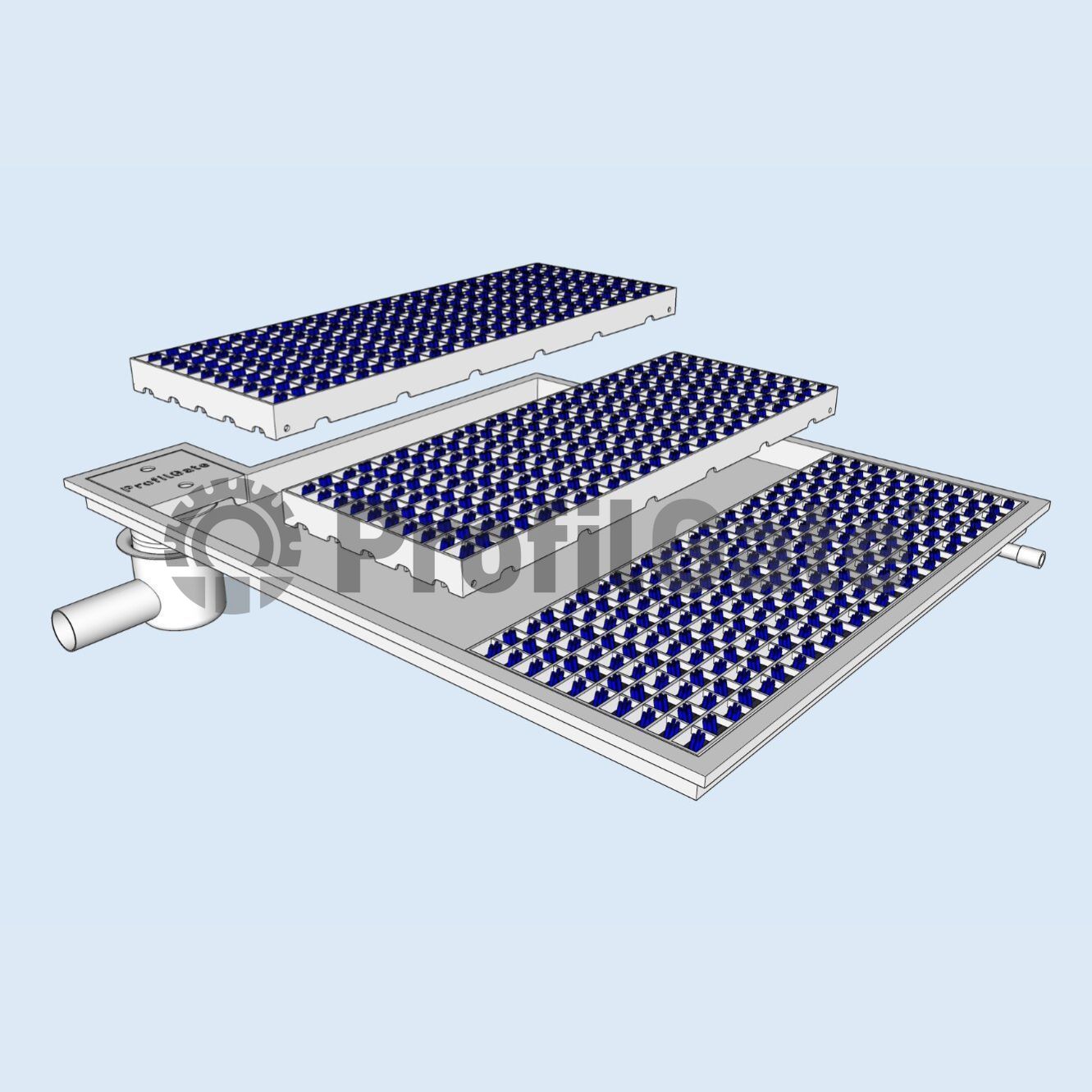

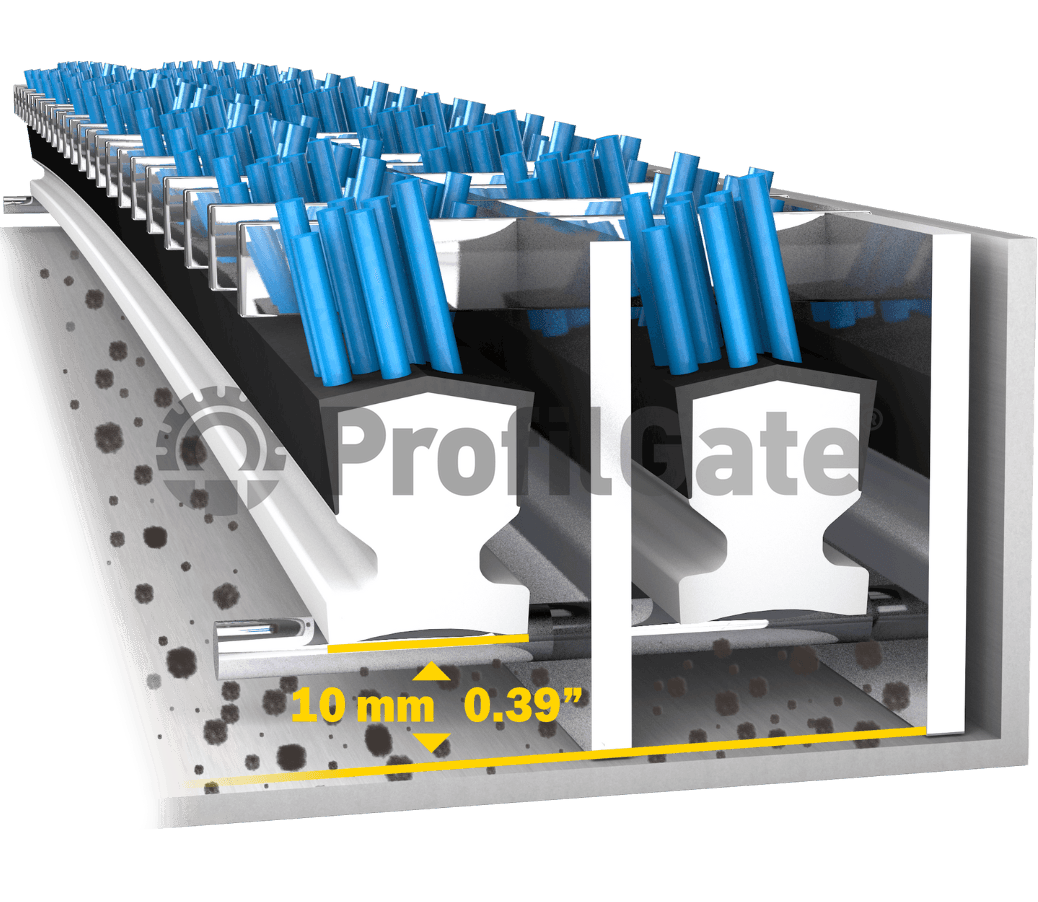

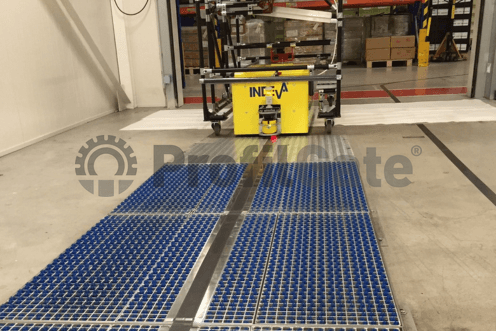

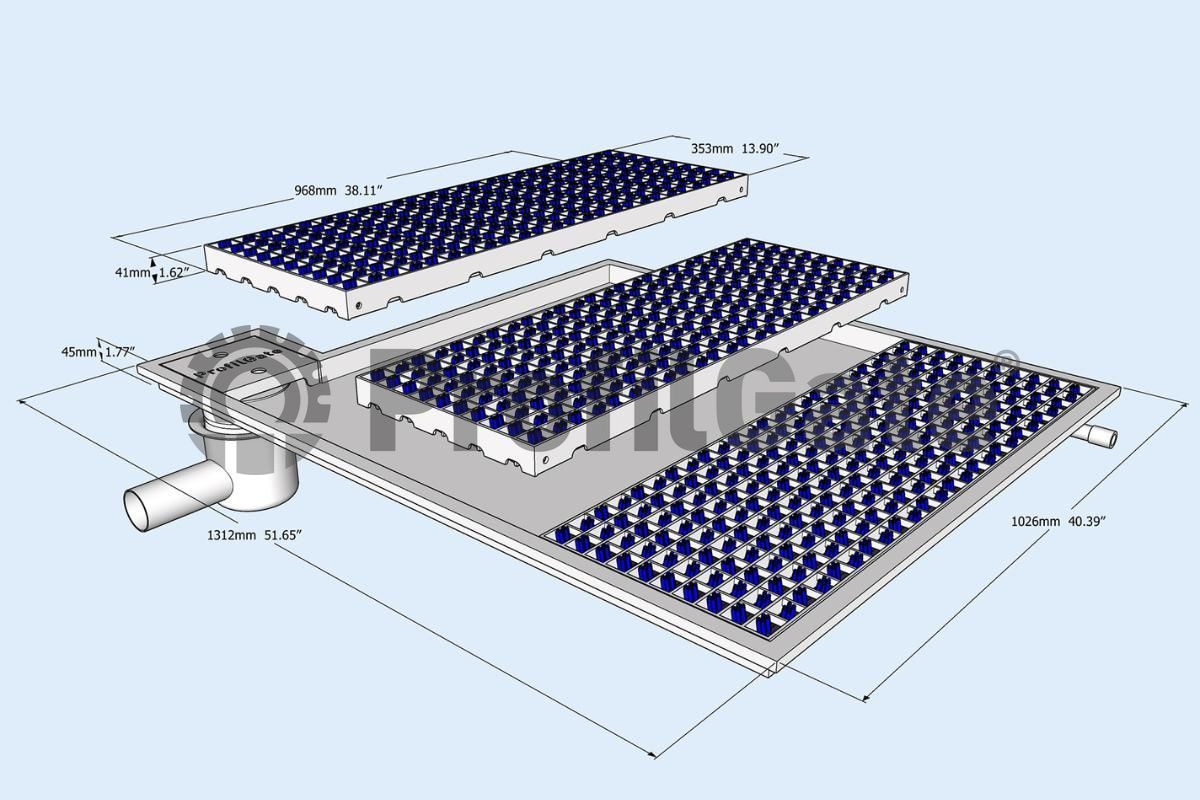

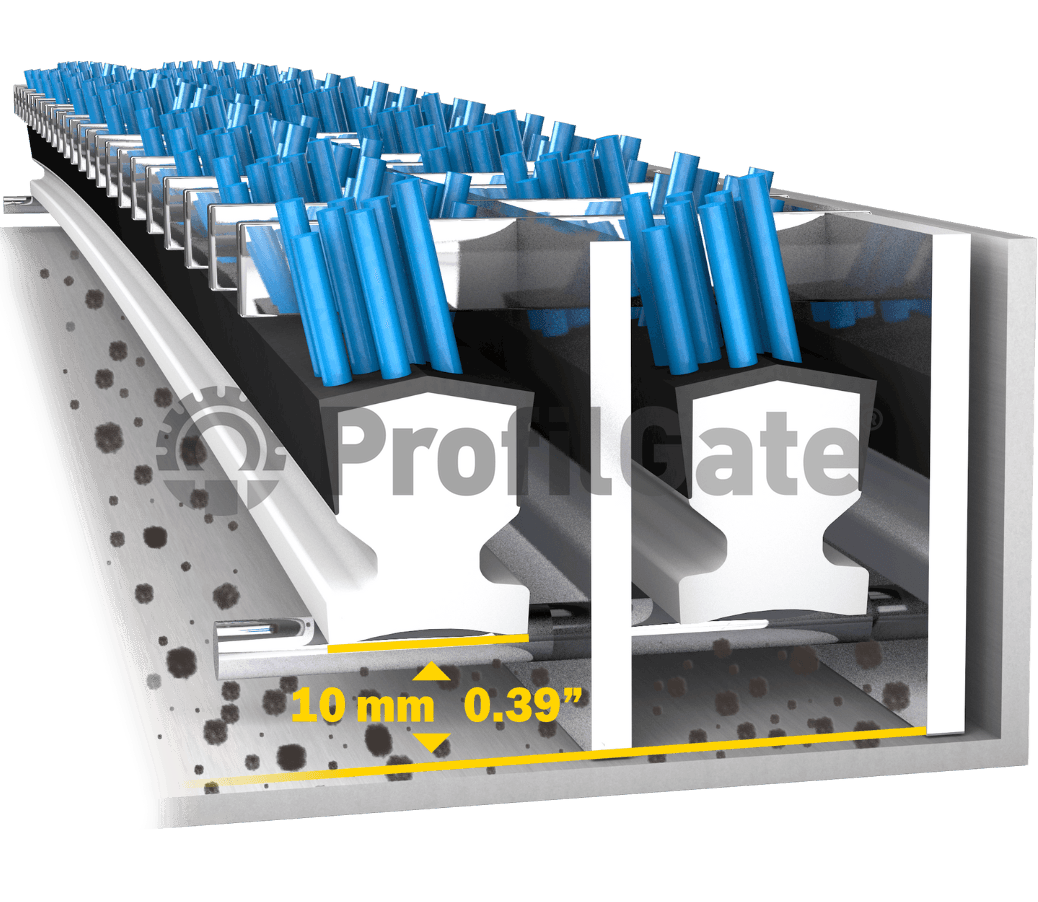

The stainless steel tanks of the i-aqua series have a medium supply and a drain. This allows water and disinfection medium to be supplied and wastewater to be drained. The medium reaches the treads as it passes over them due to the capillary action of the bristles. In this way, ProfilGate® aqua hygiene sluices help to prevent the spread of germs into high-care areas and to implement hygiene concepts.

We recommend our dosing station for medium supply. It fills the disinfection basin either manually or automatically. This saves time-consuming resharpening and ensures constant optimum disinfection performance.

If required, our ProfilGate® aqua spray model also cleans and disinfects the underside of boxes, pallets and industrial trucks. This is particularly useful when transport equipment and boxes are parked in high-care areas. ProfilGate® aqua spray is hygienic and process-safe because it cleans not only the rollers and wheels, but also the underbody. In addition, the system is integrated into the transport path and cleaning can be individually adjusted.

The stainless steel grate is ideal for access routes travelled by industrial trucks with wide rollers, such as pallet trucks.

ProfilGate® i go-series Models:

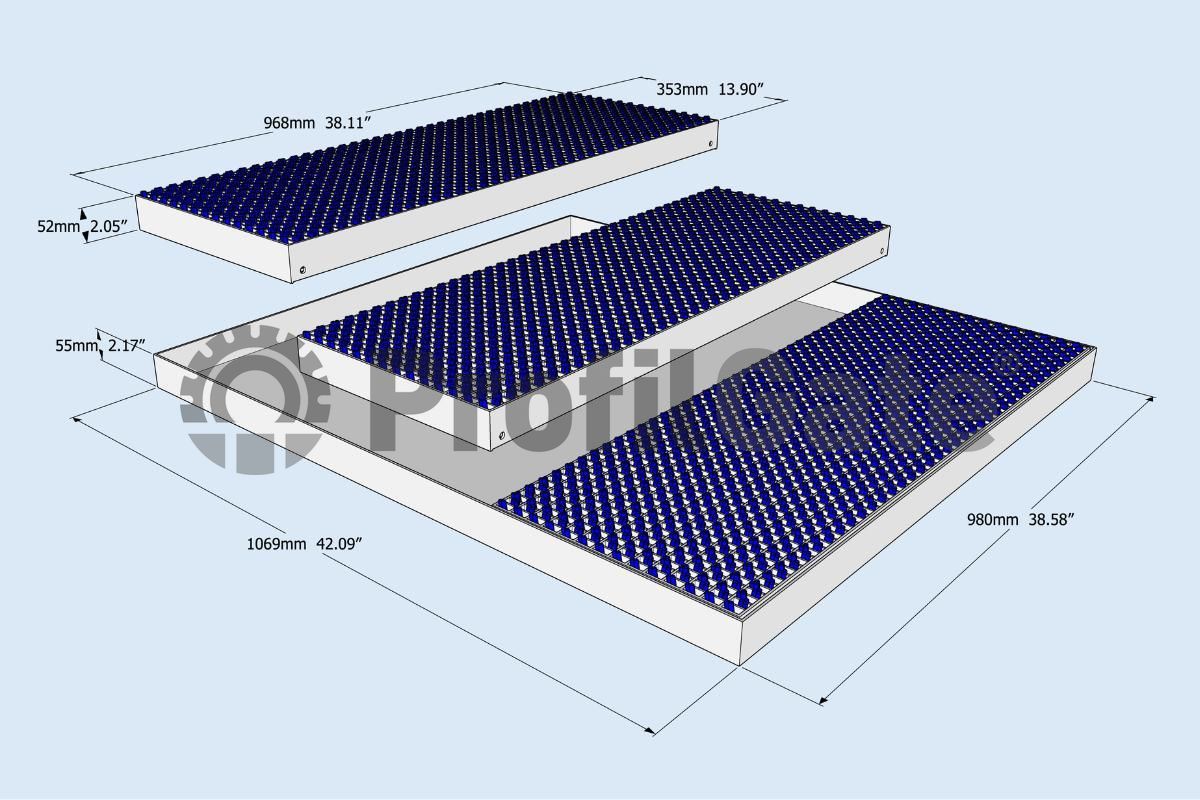

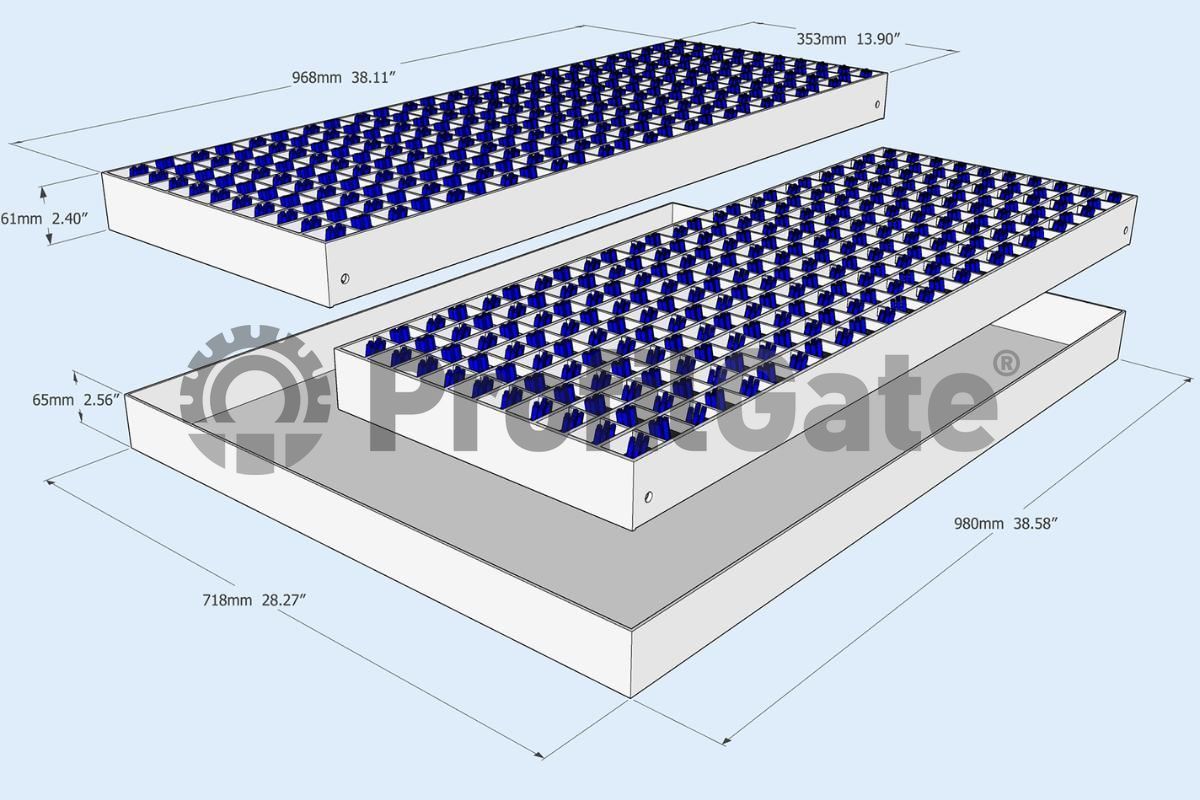

ProfilGate® i45 aqua

– Wide meshes for bigger wheels

– Designed for high loads

– Plain and smooth grate surface

– Active cleaning and disinfection by additives

– For > 100 passages per day

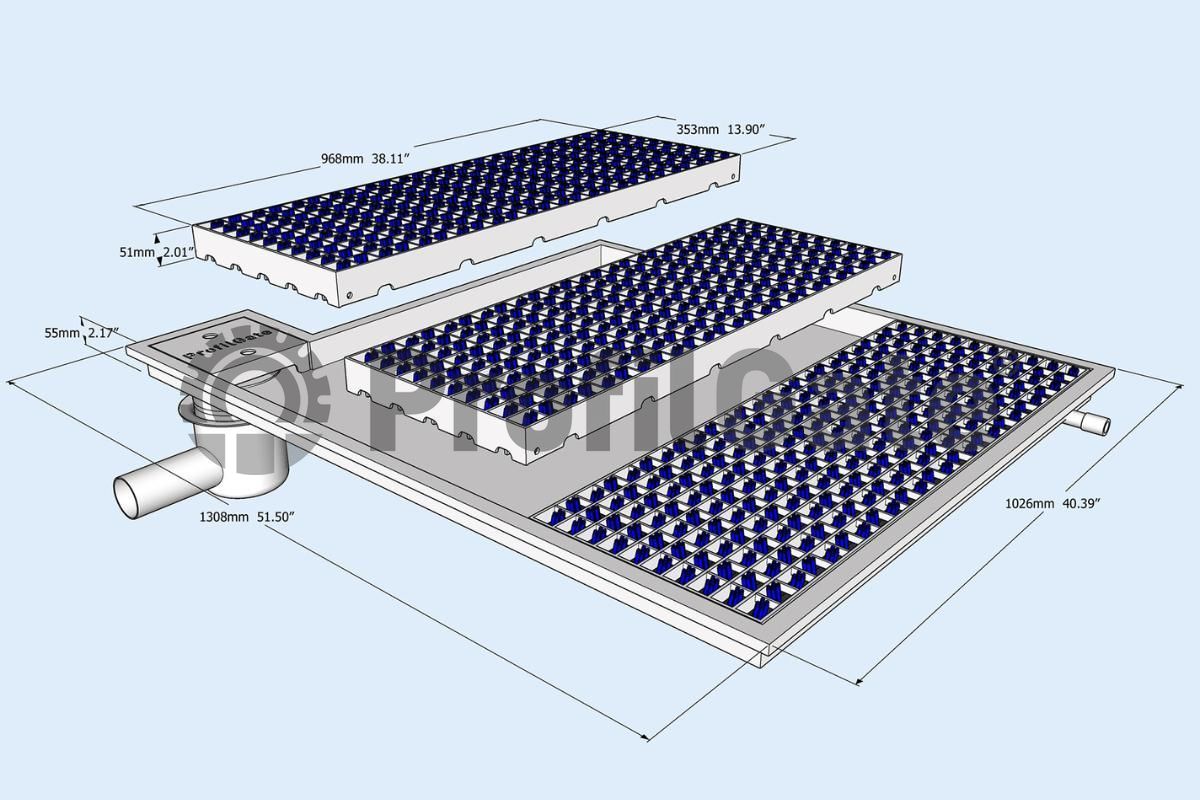

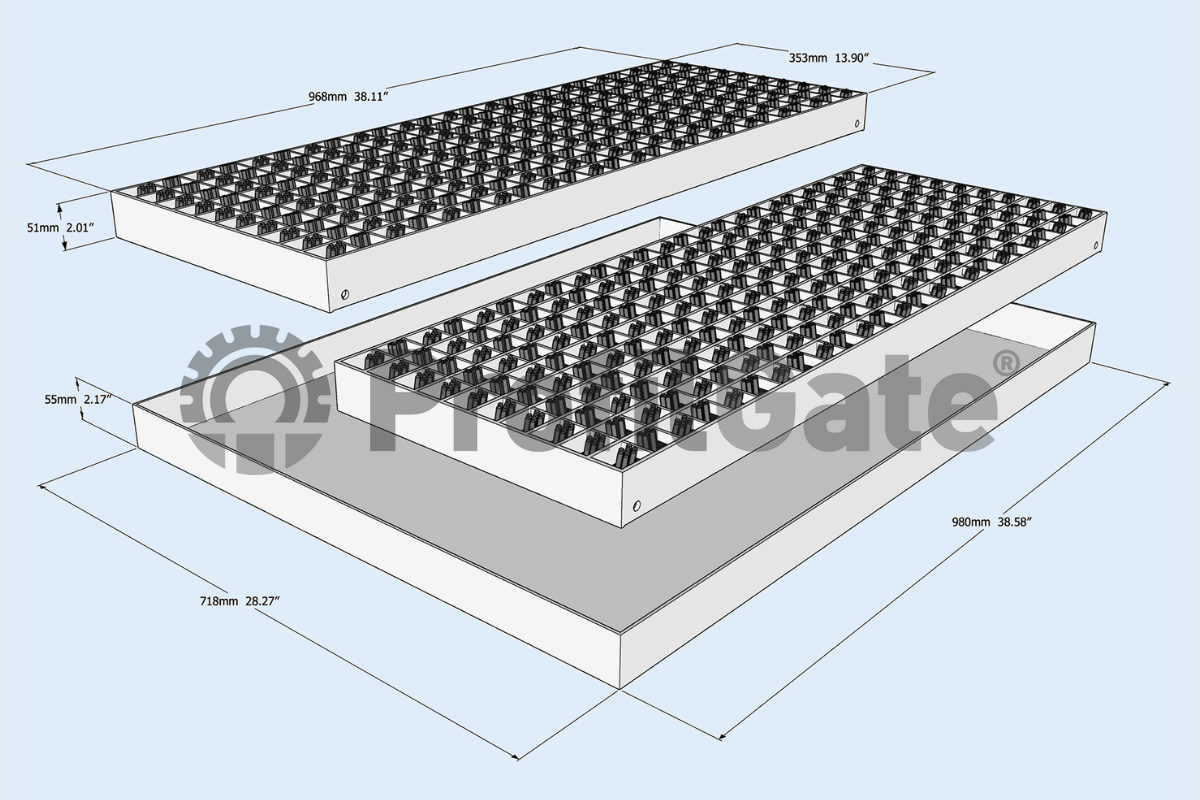

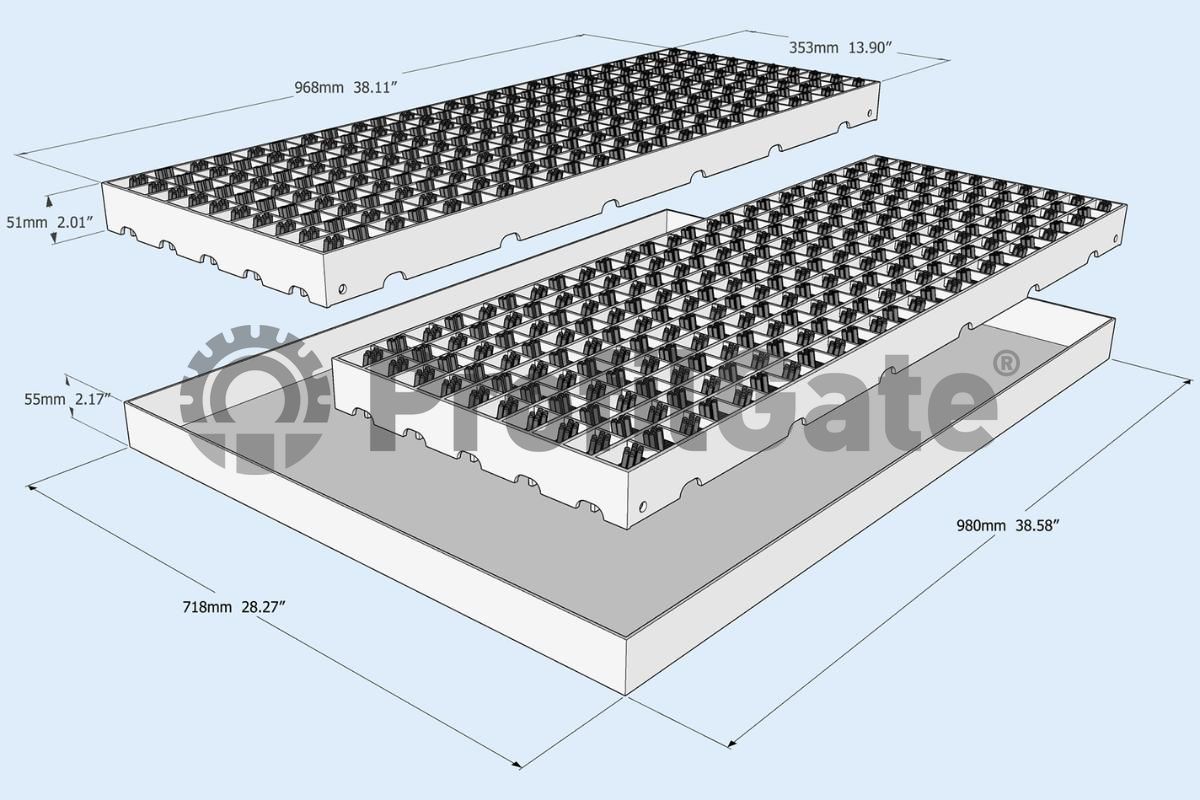

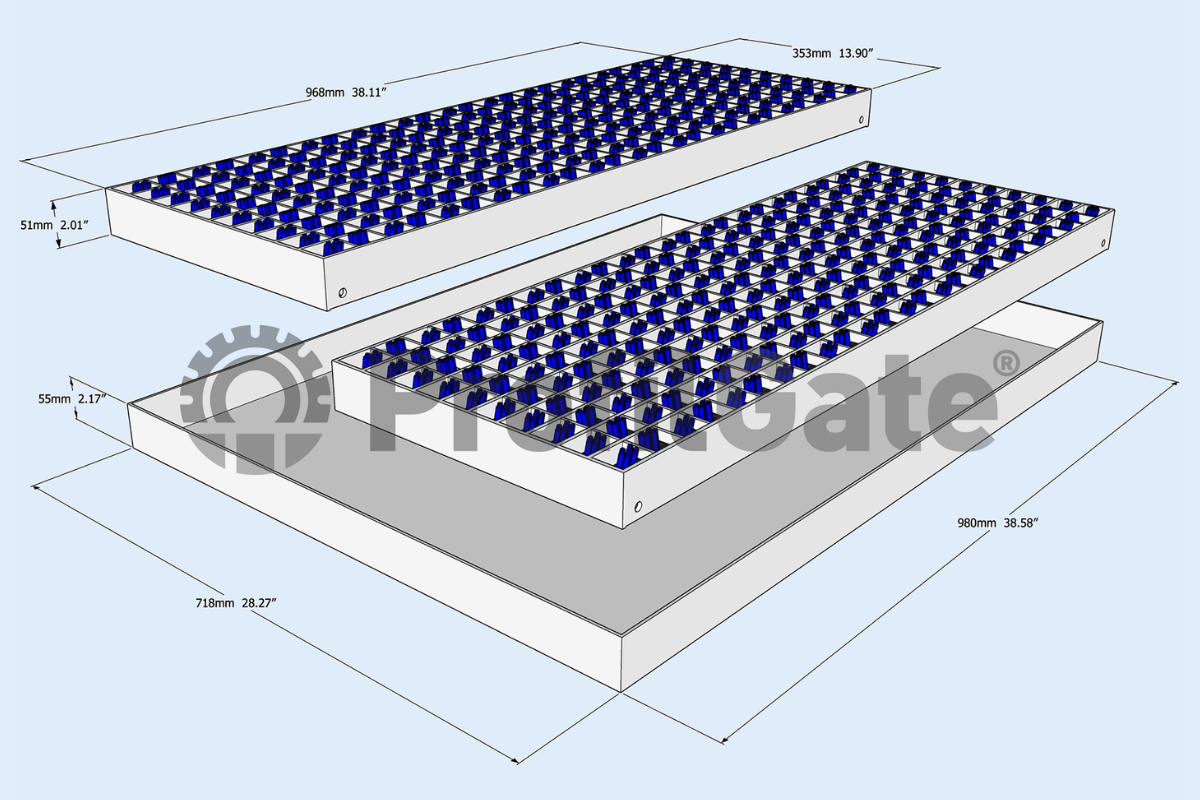

ProfilGate® i55 aqua

– Integrated spray lances

– For cleaning pallets, large boxes and industrial trucks

– Specially developed for the food and chemical/pharmaceutical industries

– Hygienic and process-safe

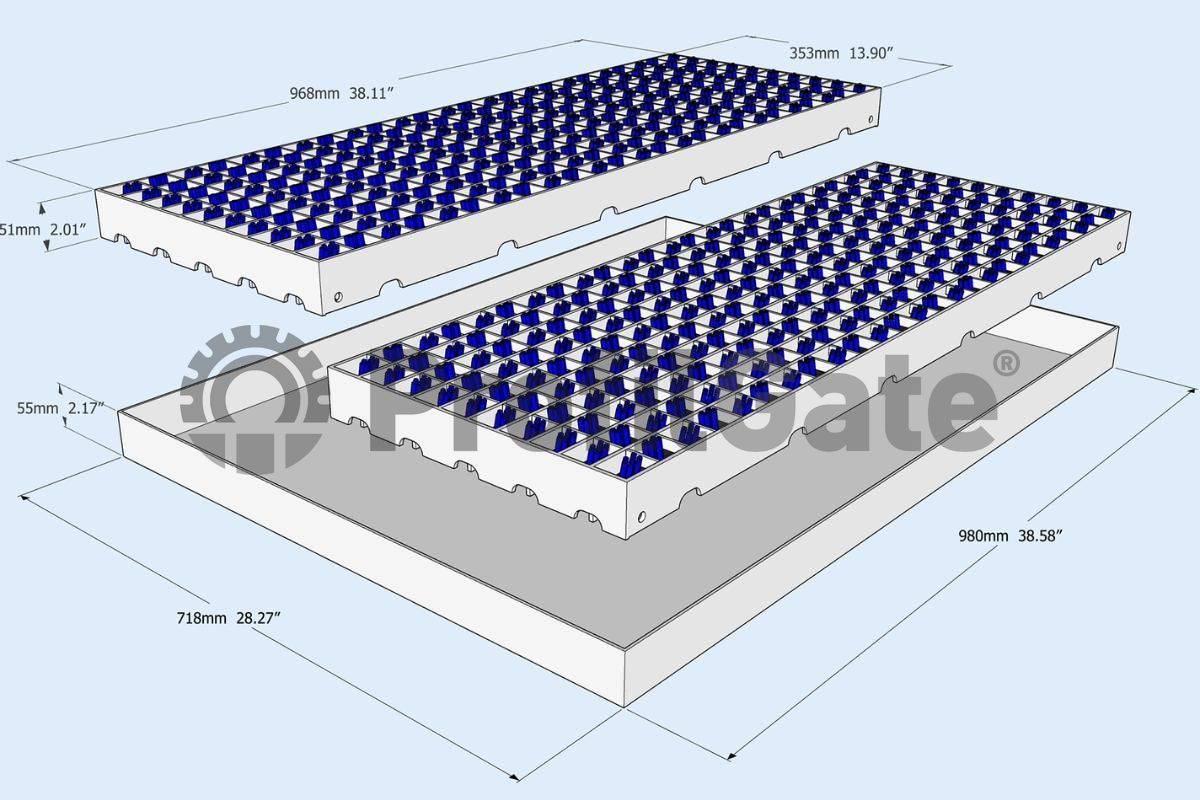

ProfilGate® i55 aqua spray

Ideal for cleaning plastic boxes

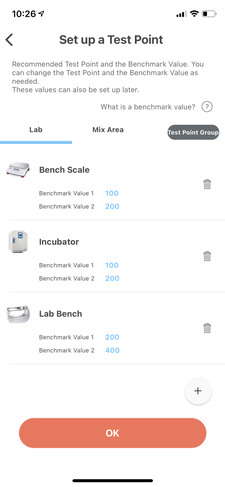

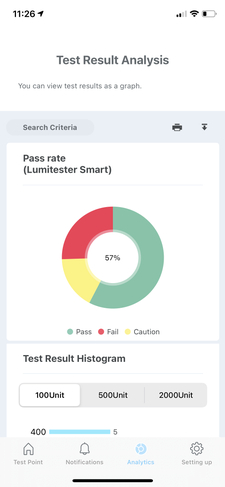

Exportable Data and Reports for Regulatory Compliance

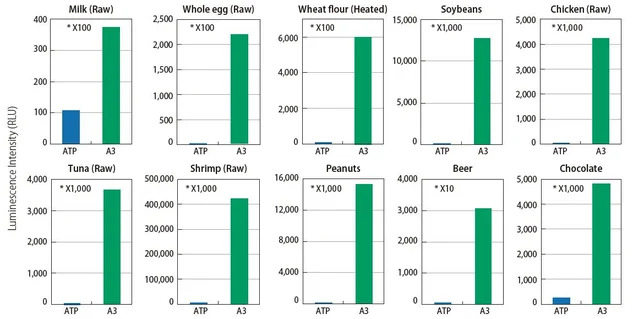

Exportable Data and Reports for Regulatory Compliance See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t