So how can we prevent the risk of Listeria contamination?

Currently, the most effective way to prevent contamination is to control it. We can effectively manage Listeria by providing all employees with proper training on contamination prevention, cleaning, and sanitizing procedures. Listeria often thrives on dirty floors, drains, cleaning and washing areas, food contact equipment, walls, ceilings, compressed air and HVAC systems, permeable surfaces, open seams, cracks, crevices, and hard-to-reach or hard-to-clean parts of equipment. Even with the best cleaning and sanitation program in place – listeria can still survive. That’s why you also need a robust and regular environmental monitoring program to identify potential hotspots. This targeting adds extra control and ensures cross contamination does not occur in other cleaned areas.But is there another way? A safer solution that you can just add to a product that simply targets and destroys listeria?

View our innovative yet natural solution to combat listeria here.

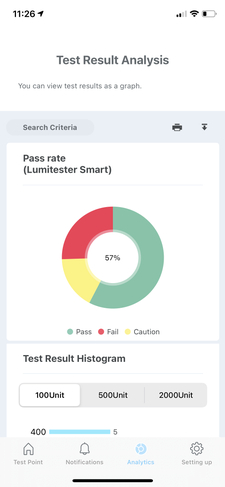

Exportable Data and Reports for Regulatory Compliance

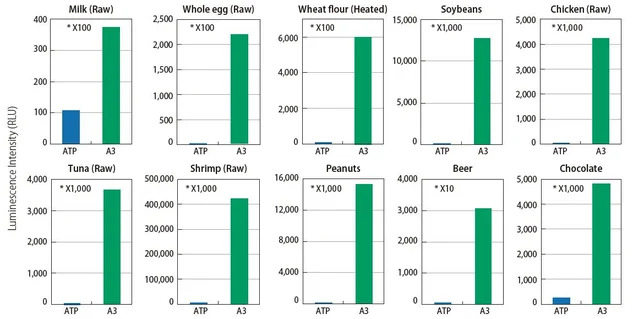

Exportable Data and Reports for Regulatory Compliance See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t